© Railway Wonders of the World 2012-

The Locomotive “Booster”

How the Tractive Effort of the Engine is Increased by Fitting an Independent Auxiliary Motor to the “Loafing” Trailer Axle

SCHEMATIC DIAGRAM OF BOOSTER AS APPLIED TO THE LOCOMOTIVE. The trailing axle is converted into an independent motive-

IN the struggle between steam and electricity for supremacy in railway operation one outstanding feature of the electrical principle is persistently driven home. This is the ability to squeeze out appreciably more power, When the occasion arises, to give rapid acceleration to the train. Without a doubt this represents an advantage over the familiar steam rival which cannot be ignored. It may be available for only a limited period, but, as a rule, this is more than sufficient to get the driver out of a tight corner. The “overload ” capacity of the electric locomotive constitutes a reserve of power which it is impossible to produce under steam conditions by conventional methods.

Obviously economy and efficiency demand that the load attached to the locomotive shall be the maximum the steam unit can haul at the required speed, and over the grades encountered, in accordance with the assigned timing schedule. We find this principle carried into effect in the composition of our trains, especially the long-

The hauling capacity of the locomotive is governed by the relation between the tractive force developed and the resistance of the train. The more pronounced the difference between the two the greater the reserve for acceleration. As the speed increases, the tractive effort, or draw-

The steam locomotive driver has always hankered for a means of getting a little more power out of his machine at critical moments to enable him to accelerate more rapidly to road speed. Many and varied devices have been evolved to satisfy this desire, but they have failed to substantiate their claims in practice. The draw-

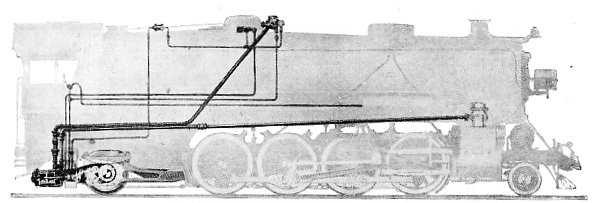

BOOSTER MOUNTED ON TRAILER TRUCK. It comprises the fitting of a two-

In this evolution other troubles have been precipitated, as, for instance, the necessity to introduce a truck, and pair of wheels behind the driving wheels, to support the fire-

With the creation of larger and heavier locomotives the significance of the dead weight of the idle trailing axle became more and more apparent, and the attention of Mr. Ingersoll, the assistant to the president of the New York Central Railroad, became absorbed in the possibility of converting this adjunct to useful purpose. He conceived the idea of compelling it to perform dual duty.

His ultimate conception was novel. He converted the trailing axle into an independent motive-

How the Booster Operates

To this invention he applied the generic name “booster”, and it was subjected to searching test on the bench, with the result that it revealed such promising possibilities as to induce experimental attachment in 1919 to a locomotive. Trials on the road fully substantiating the inventor’s expectations, the booster passed into established practice, and was introduced to the railways of the world through the Franklin Railway Supply Company, of New York City.

This device, one of the most ingenious recent improvements effected in the steam locomotive for the increase of power and enhancement of economical and efficient operation, has its functions fully explained by its title -

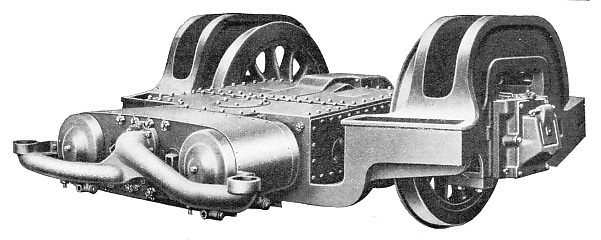

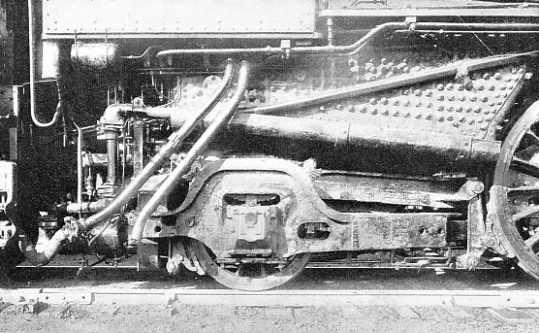

SIDE VIEW OF BOOSTER. The simple engines have cylinders 10 inches in diameter by 12 inches stroke. They are of the double-

It is a simple auxiliary comprising the fitting of a two-

The engine is of massive construction and completely enclosed, the gear cover forming an integral part of the casting. At the rear, or head of the cylinders, is a large manifold for the live and exhaust steam; the lead for the former is taken from the dome, while the latter is taken from the booster to the head of the locomotive to be exhausted with the steam from the engine cylinders through the blast pipe and smoke stack in the usual manner.

Control of the Booster

Control is semi-

Upon the American railways the “Mikado” design is generally accepted as the most efficient type of engine for heavy freight duty, though some systems have adopted the “Santa Fe”, or 2-

The train-

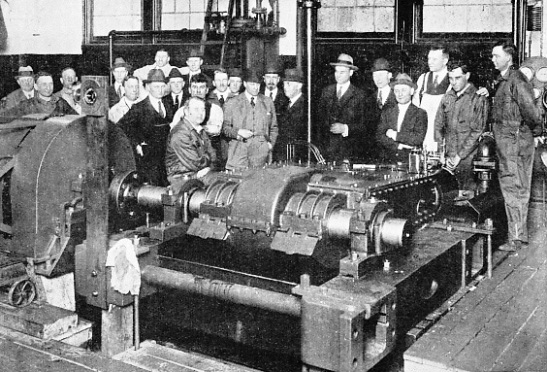

BOOSTER UNDER TEST ON BENCH-

The device was subjected to searching test on the bench, and proved so satisfactory that in 1919 experimental attachment to a locomotive was carried out with equally good results.

As a rule, so far as it is practicable, the grades are grouped, or “bunched”, as it is termed, and the locomotive power selected for coping with the physical characteristics of that section. The succeeding division may be appreciably easier, rendering it uneconomical to continue the use of the locomotive employed upon the preceding section; one of less power will prove adequate for the purpose. It has been discovered, also, that the booster-

The extent to which this device is reducing pusher service is distinctly noticeable. On one road the pusher has been regularly employed to assist the train over 70 miles, though its services are not required continuously throughout this distance, nor its power demanded for more than 7½ miles. Now, a booster-

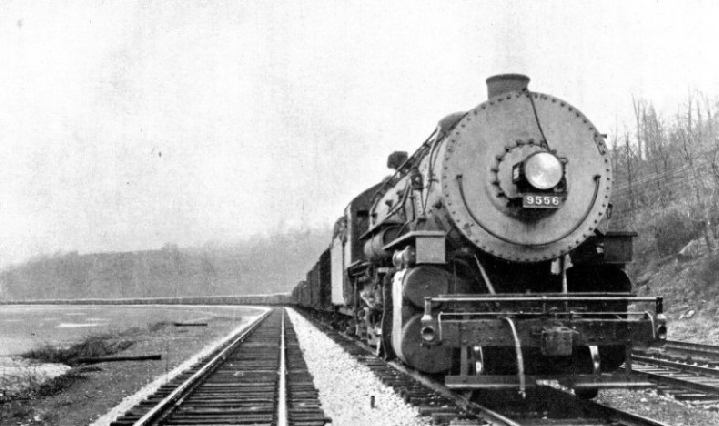

LONG FREIGHT TRAIN HAULED BY LOCOMOTIVE WITH BOOSTER. Above the piston valve cylinder is seen the header, or connexion, for the exhaust steam-

In this instance the booster is saving the wages, fuel, and wear and tear of the locomotive which was employed as helper, as well as reducing the interference with the other traffic incidental to the pusher locomotive dropping back to its station. The booster represents an investment of about one-

In mountainous districts this economy becomes somewhat more pronounced. To a material degree the weight of the locomotives upon such sections is governed by the strength of the bridges and trestles. In this instance the booster fitted to the existing locomotive is able to solve the problem with eminent satisfaction, inasmuch as its inclusion only increases the weight of the locomotive by about 5,000 lb.

BOOSTER APPLIED TO LOCOMOTIVE. It is fitted with a main transverse shaft on which is mounted a pinion, while on the trailer is a similar but larger gear-

This may be explained in another way. By fitting a locomotive of the 2-

The booster also promises to revolutionize suburban train operation. In this service, especially during the hours of pressure, the train weights are heavy, while time is occupied in the acceleration to road speed upon leaving a station. It is this defect which has stimulated the electrification of the short-

For the heavy suburban service of the American railways, extending up to 50 miles, powerful “Atlantics” were built, but they are proving inadequate for the traffic, and so are giving way to the “Pacific” type, which, however, yields far more remunerative performance on longer hauls. Certain railways have fitted boosters to their “Atlantics” and have discovered their starting effort to be improved 40 per cent, thereby, thus enabling them to release their “Pacifics” for the more remunerative duty. It may be mentioned, incidentally, that in the case of the “Pacific” type, the inclusion of the booster has been found to increase its starting effort by 27 per cent.

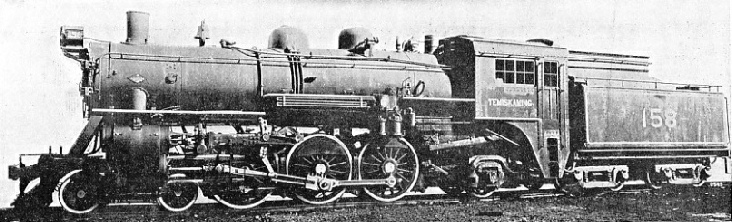

“PACIFIC” BOOSTER LOCOMOTIVE ON THE TEMISKAMING & NORTH ONTARIO RAILROAD. This line, traversing the hinterland of Northern Ontario and the Cobalt country, has heavy grades. By the inclusion of the booster, starting effort has been increased by 27 per cent.

The reserve of power which the booster represents ensures smoother and steadier starting, which, in the case of passenger trains, conduces to greater comfort in travel. Its advantages in this respect are brought home more effectively in connexion with the long freight trains, such as are common to the American, Canadian and other Dominion railways. Steady smooth starting reduces shock upon the draft-

The trailer-

Investigation of the new development is proceeding in Great Britain, the pioneer effort in this direction being made upon the North Eastern division of the London and North Eastern Railway. The railway serves the busiest heavy industrial corner of the country, handling an enormous volume of coal, and having roads with somewhat severe grades; also, the marshalling yards have a dense traffic, and the operation of these can be appreciably facilitated with locomotives invested with the power to get away quickly.

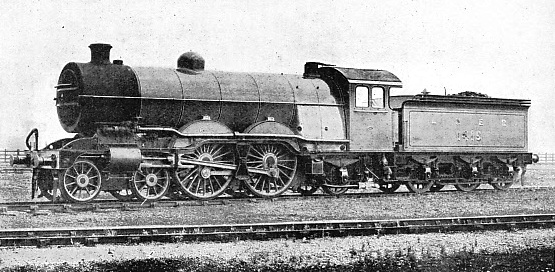

LNER EXPRESS PASSENGER ENGINE, “ATLANTIC” TYPE (4-

You can read more on “The Development of the Locomotive Fire-