The World’s Most Famous Railway

The story of the London and North Western Line

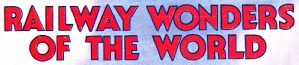

THE TUBULAR BRIDGE, designed by Stephenson, over the Menai Straits.

PROBABLY no other steel highway is so famous throughout the world as that known today as the London and North Western Railway. While, as an entity, it represents a combination of some fifty systems, it is interesting historically because its nucleus was the celebrated Liverpool and Manchester Railway, which was opened for traffic on September 15th, 1830, and on which the historic “Rocket” carried off the first prize of £500 in the Rainhill locomotive trials. It was this competition and its startling results that opened the eyes of the various countries to the possibilities of the railway and steam loco-

While the operation of this pioneer line demonstrated the revolution that was destined to be wrought by this means of communication, the construction of the thirty miles between the two great commercial centres of Lancashire also brought home the fact that the railway builder, in his efforts to cleave a narrow passage for the ribbon of steel, would have to be prepared to be thrown against baffling obstacles which would tax his ingenuity, resourcefulness and determination to a supreme degree. Seven miles west of Manchester, and extending over twelve square miles, is the morass known as Chat Moss. The railway was plotted to run across it. At first, owing to the fact that extensive drainage schemes had been carried out, it was thought that the bog would not offer any serious difficulties, but when the builders came to grips with it, they soon ascertained that the statements concerning its character and the obstruction it would offer to their advance were by no means over-

This brought him into touch with railway engineering in the field, and he established his name as a constructional engineer by the ingenuity and fertility he displayed in subjugating the treacherous Chat Moss. As it was impossible to build up an embankment merely by the discharge of spoil, since the latter immediately sank into the bog’s slimy, unstable mass, he conceived the idea of laying the earthworks upon a brushwood foundation. He fashioned a substantial mattress of hurdles, interlaced with heather and tree boughs, which was laid upon the surface of the bog, and upon which the spoil was dumped. Under the superimposed weight the mattress sank deeper and deeper into the morass, until it gained a point beyond which it would not move. The embankment was as firm and as solid as if it were resting upon a rock, and inasmuch as the submerged mattress was certain to become stronger as time passed, owing to its becoming water-

As the promoters of the Liverpool and Manchester Railway were engaged upon a pioneer undertaking, and were quite ignorant of the revenue-

When the Liverpool and Manchester Railway had settled down, and had become an assured success, other small systems grew up around it. Among these was a short line, four and a half miles in length, which, branching from the main line, linked up with Warrington. Owing to Robert Stephenson’s success with the parent line, he was entrusted with this work. Another company, the Grand Junction Railway, secured the requisite Parliamentary sanction to continue this Warrington branch to the south through Crewe to Birmingham. In the same year was granted permission also to build a railway 112¼ miles in length from London to Birmingham. At the latter point it was to connect up with the Grand Junction Railway, so that through and direct communication would be offered between the Metropolis, Manchester and Liverpool. Robert Stephenson was entrusted with the survey of the London to Birmingham section, and afterwards became the chief engineer to the undertaking. Under his direction the first turf was cut at Chalk Farm on June 1st, 1834, and work was prosecuted so vigorously that the north was in railway touch with the Metropolis on September 20th, 1838.

But although the 112 miles to Birmingham were completed within such a short time, it must not be inferred that the work was straightforward, easy, and free from harassing difficulty. Far from it. The building of the Liverpool and Manchester line, despite Chat Moss and the heavy excavation in Olive Cutting, was child’s play in comparison with the London and Birmingham Railway. The cost of construction was based upon that of the former line; contractors regarded the under-

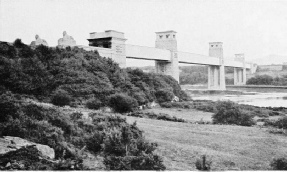

THE MAIN SHAFT IN THE KILSBY TUNNEL. This work, owing to water trouble, proved the most difficult and expensive on the whole system.

In order to reach Rugby the location of the line cut under the Kilsby Ridge. A tunnel 2,423 yards in length was inevitable. It seemed a straightforward job, because the borings which were driven in the customary manner, to determine the geological formation through which the bore was to extend, did not present any abnormalities. So the contractor estimated that he could complete the task for £99,000. Considering that up to this time a tunnel exceeding half-

The contractor started operations in June, 1835, but ere many weeks had passed he learned to his dismay that the borings were completely unreliable. When he came to sink his shafts through what he had been led to expect to be sound earth and rock, he stumbled against slippery shale, quicksand and water, of which, strange to say, no inkling had been given in the borings, as they had missed these treacherous spots. The contractor persevered, hoping against hope that he would get through this treacherous stratae as he sank his second shaft deeper, but after nine months’ heartbreaking disappointments and fighting against overwhelming odds, he threw up the job.

The Kilsby Tunnel became a nightmare. The water trouble scared every other contractor; not one could be induced to quote a revised price for its completion. Accordingly, the railway company was forced to take it over. Robert Stephenson came upon the scene, surveyed the prospect, and finally came to the conclusion that the water trouble was probably quite local; was not fed by subterranean springs, and that, provided adequate pumping plant was erected, the shaft could be pumped dry. He set up powerful steam-

By the aid of a small army of 1,300 navvies, who toiled day and night incessantly, the tunnel was completed by October, 1838 -

Owing to the treacherous character of the earth through which the bore was driven, the tunnel had to be lined throughout, and for this purpose 30,000,000 bricks were used. The two shafts which are used for ventilating purposes are each 60 feet in diameter, by 130 and 60 feet in depth respectively. By the time the rails were laid, the Kilsby Tunnel had run away with over £300,000 -

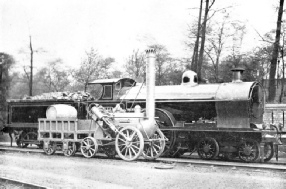

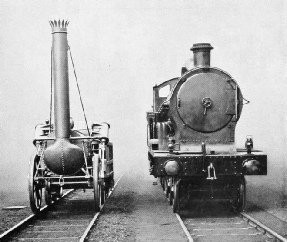

THE OLD AND THE NEW. Full size working model of Stephenson’s “Rocket”, which won the £500 prize at Rainhill in 1830, beside the 5,000th engine of the London and North Western Railway, built at Crewe works in 1911.

At first the three companies which offered railway communication between London, Manchester and Liverpool promised to work harmoniously together, but in reality differences of opinion arose, and they were at daggers drawn. In order to provide a more direct route between Birmingham and Manchester than that offered by the Grand Junction Railway another company -

The London and Birmingham Railway viewed this move with the greatest anxiety, as the greater part of its traffic would be filched away, and it would be surrounded by hostile interests. Thereupon the directors, after a solemn discussion of the outlook, decided to recede from their untenable hostile position, made overtures to the Grand Junction Railway, and suggested that the two opposing forces should settle their differences and combine. The negotiations proved successful, and in 1846 the union was completed, the different concerns being bound into a homogeneous whole under the title of the London and North Western Railway.

When the first railways forming this system were taken in hand, the engineers, owing to lack of experience, generally clung to the theory that a locomotive would not be able to work by adhesion purely and simply over gradients exceeding about 1 in 330. Accordingly, the lines between London and Manchester were plotted so as to conform with this prevailing opinion. This lack of knowledge proved a fortunate circumstance in the long run, inasmuch as the company has been spared that costly realignment and reconstruction which has harassed other railways so sorely, owing to the adverse influence exerted by the heavy grades in their original lines.

Taken on the whole, the Birmingham section of the London and North Western Railway is one of the most level lines in the world, and is conducive to high speeds and economical operation. There is no bank exceeding 16 feet per mile -

The general belief that a rise of 1 in 330 represented the maximum permissible for working by steam provoked a curious situation upon the section of the line between Euston terminus and Camden Town. Although the surveyors struggled hard, they found it absolutely impossible, owing to physical configuration, to secure a rise of less than 1 in 70 between the two points. They made no attempt to work it by adhesion. Instead, all trains proceeding out of Euston were assisted as far as Camden Town by a cable, which was hitched on to the train and wound in by a stationary winding plant, comprising two engines placed underground at Camden Town. They were of 60 nominal horsepower, and the main pulleys had a diameter of 20 feet. The rope was about 13,000 feet in length, and cost over £450.

THE FAMOUS OLIVE CUTTING ON PART OF THE THE LIVERPOOL AND MANCHESTER RAILWAY, now forming part of the London and North Western system.

The system of operating this cable incline was quite in keeping with the times. As they were pre-

When the line was first built, the metals were laid on stone blocks, of which 152,000 tons were used upon the 112 miles out of London, at a cost of £180,000. A similar practice had been adopted on the Liverpool and Manchester Railway, where the permanent way rested upon a solid foundation, although on those parts where somewhat soft land was encountered wooden sleepers were used. However, the stone blocks were found to make the road hard and uncomfortable, and inflicted severe wear and tear both upon the track and rolling stock. On the other hand, the stretch of line laid with wooden sleepers was found to be more comfortable, easier, and reduced maintenance expenses. Accordingly, after lying for a short while, the stone blocks between London and Birmingham were removed in favour of wooden sleepers.

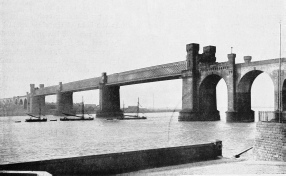

THE RUNCORN BRIDGE OVER THE RIVER MERSEY. It is a lattice girder structure comprising three main spans each of 305 feet, with the rails 75 feet above the waterway.

From the day when the Liverpool and Manchester, the Grand Junction, and the London and Birmingham Railways were fused into one organisation, the principle of acquiring other individual roads was pursued. Thus, not only was competition eliminated, but the field of operations was widened very considerably. The London and North Western system to-

Taken on the whole, the system does not possess many important works which under present conditions would rank as startling pieces of engineering, although in the early days many achievements created intense interest, and were regarded as marvels of human activity. The Kilsby Tunnel represents, perhaps, the most interesting illustration of tunnel-

This bridge, 1,510 feet in length, comprises two immense rectangular tubes -

The tubes were then raised by the aid of a huge overhead hydraulic press, which by means of chains lifted them 6 feet at a time, the masonry How the being completed beneath as rapidly as possible after each lift. As the links of the chain could be withdrawn as required, having been made specially for this purpose, after each lift the chain was shortened, and the plunger of the hydraulic press permitted to descend. The shortened chain was then re-

THE “LADY OF THE LAKE”. Built in 1858. The driving wheel is 90 inches diameter.

The bridge was completed within the short space of five years, the first train passing through in 1850. Robert Stephenson adopted a similar bridge to span the River St. Lawrence at Montreal, for the Grand Trunk Railway of Canada. This, however, was a far larger undertaking. Two bridges of this type were built by him in Egypt, but in this latter instance the trains did not run through the bridge, but along the top deck of the rectangular tube.

Although the original stretches of the London and North Western Railway are very flat, and conducive to the fast and economical movement of traffic, the extensions of the system into Wales and north of Manchester to Carlisle proved far more difficult and expensive to build, bearing in mind the considerations of easy grade. On the main line to Scotland the ascent of Shap Fell to the summit level of 914 feet above the sea is heavy, averaging 1 in 75 for 6 miles. Similarly, in traversing many of the wilder parts of the Principality, the beauties of which have been opened up by this line, heavy expensive work was encountered. At Festiniog a tunnel had to be driven for the whole distance of 3,726 yards through solid rock. In the vicinity of Penmaenmawr the engineers have been pitted against a still more implacable enemy -

THE “CHARLES DICKENS”, which covered 2,000,000 miles -

Seeing that the London and North Western Railway, by its acquisition of the Liverpool and Manchester Railway, compasses practically the entire history of the steam locomotive, it has played a very important part in the development of the railway engine. It was on the Liverpool and Manchester Railway that the railway locomotive was born, where it assumed its type and commercial characteristics, and where the lines indicative of high speed were first worked out. From the “Rocket” to the “Sir Gilbert Claughton”, the latest type developed upon this system, or the ponderous “Mallet”, is a far cry, but despite the vast strides which have been made during the interval, fundamentally the latter do not differ from the former; the basic principles are the same.

Thus the story of the London and North Western Railway is virtually the story of the locomotive. Volumes could be written upon the latter, and the various developments that have been made, either in the interests of increased speed, augmented haulage power, improved efficiency, or enhanced economy. Many names, inseparable from the evolution of the locomotive -

THE “HARDWICKE”, which crated a record in the “Race to the North” (1895) by running from Crewe to Carlisle -

In 1847 Trevithick designed the “Cornwall”, having drivers 102 inches in diameter, and with the boiler under the driving axle. She was a failure, but when rebuilt by Ramsbottom in 1858 she retrieved her reputation. Before she was withdrawn from service in 1904 she had covered 919,526 miles. These huge single drivers put up some fine speed records, especially when the conditions were favourable. The four-

THE “IONIC”, which hauled a train from London to Carlisle -

The first engine which was built at Crewe for the express passenger traffic weighed about 20 tons, and hauled a load of some 40 tons at speeds ranging between 20 and 30 miles per hour. The latest express engines which have been turned out of the Crewe shops exceed 100 tons complete with tender, and are capable of hauling loads weighing 400 tons at 60 miles an hour. The latest achievement of the London and North Western Railway is the “Sir Gilbert Claughton”, which has been described in another chapter.

The railway has achieved a world-

FRONT VIEWS OF THE “ROCKET and the 5,000th engine built at Crewe.

You can read more about

“The London & North Western Railway”

“On the Footplate of an Express” ,

on this website.