A Trip on the Footplate at Seventy Miles and Hour

LOCOMOTIVES - 7

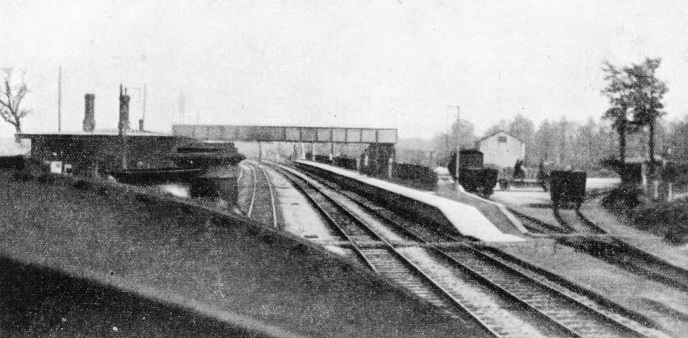

THE “THROUGH” ROAD. When the main line express is scheduled to pass through intermediate stations the up or down main line - the two centre tracks in this picture - must be kept clear.

FOR many years there has been an element of mystery and something of the secret society about the locomotive departments of the railways. Members enter it in early youth, promise faithful service, seldom disclose what takes place in their daily work, and make it a “"job for life”.

Only in recent years has that veil of secrecy been lifted; and that it has been lifted is due partly to the GWR, who now welcome visitors to the Swindon works. But in the main this element of secrecy persists. The running sheds of a railway company can be visited only by special permit, and to obtain a footplate pass the applicant must show that he has some very special reason for wanting to ride on the engine.

Driving is a mystery, even to many of those who have spent a lifetime in the service of the railway. And even those who are familiar with it all are always eager to learn more about it.

The most interesting time to visit the locomotive sheds of any of the companies is at midnight. Outside, the streets are quiet, but inside the sheds there is considerable activity.

The shed is a long building which has six tracks or “roads” in it. Between each pair of rails the ground has been dug away to form a pit so that men can stand upright under an engine and carry out “running repairs” - that is small jobs such as taking up slack in connecting-rods, big ends, adjusting spring hangers, hornblock wedges, and brake gear. In the old days all this had to be done by the light of torch-lamps, which resembled a small tin teapot with a lighted, wick stuck in the spout; but to-day many pits are wired and provided with plugs so that electric hand-lamps can be used.

Not all sheds are of this particular shape; some are round, with a turntable in the middle, and tracks radiating from it like spokes of a wheel; others are fan-shaped, with a turn-table outside, all tracks from the sheds going direct to the turn-table. Both these types are known as “round-houses”, the latter type being much favoured in America.

Numerous engines of various types are standing in the shed, some in steam, and some “dead” - which is the locomotive man’s term for a cold engine. Several of these are in the care of the running repair staff. In the firebox of one big goods engine a boilersmith “nobbles up”, as he calls it, some leaky stayheads. On another, the sanding gear is all down and the pipes are being cleaned out. On yet another a fitter is replacing a gauge glass and grinding in the cocks; while on a fourth the smoke-box door is open and a man is busy on the super-heater header. At the end of one row a boiler is being washed out. Just as the domestic kettle “furs up”, so does the boiler of a locomotive; and if it were not frequently cleared out, the spaces between the firebox and the shell of the boiler would become choked solid with scale and dirt, the plates would overheat, and the firebox collapse. In most sheds, hot water at high pressure is now used. The boilers are provided with a number of plugs, which are removed and the hose nozzle inserted in each in turn. The dirt runs out through large plug-holes or mud-holes round the bottom of the firebox; and enough scale comes out of a boiler of moderate size to fill a wheel-barrow.

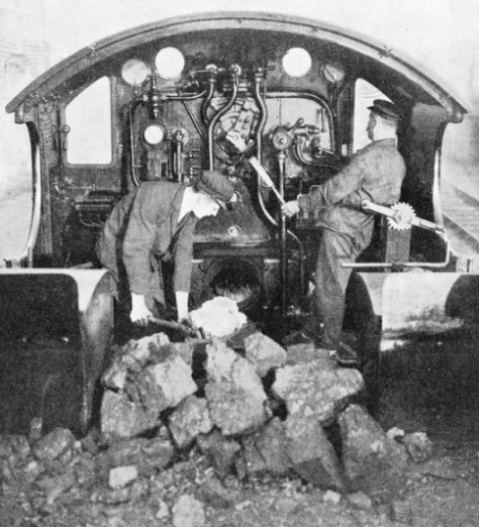

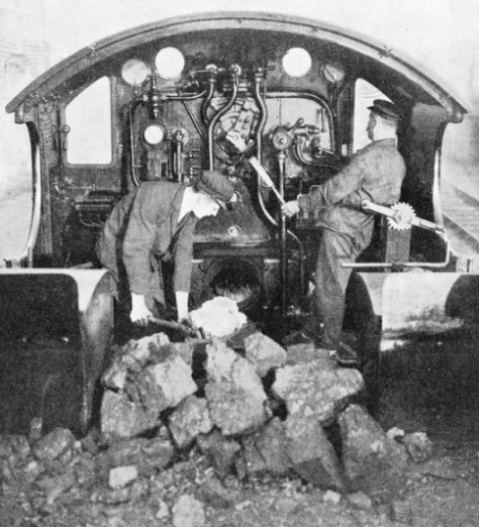

INSIDE THE CAB of a Great Western locomotive. The driver is holding the regulator handle and driving from the right-hand side, as is customary on the GWR. To the right of the regulator is the vacuum brake valve, while behind the driver is the notched disk of the screw-reversing gear.

The engines in steam are being attended to by gangs of cleaners, since they will be first out in the morning. In the old days on some of the railways each engine had its own cleaner, who “followed” it; that is to say, he arranged his hours of duty according to the working of the engine. Engines worked in a “link”, and there would be a list of “turns” - early “turns” working the first trains in the early morning, and late “turns” working evening services. Each engine in the “link” worked through the whole list, so that it went out at a different time every day, but it had the same driver and fireman. Competition was keen in the sheds as to whose engine looked the smartest, but those days are now gone. Under modern conditions engines, especially passenger and goods tanks, work long spells of duty; their crews are changed on the road; and during the short time the engines are in the sheds they are cleaned by a gang of about six cleaners. Dirt is usually removed by “sockers” of cotton waste soaked in oil or paraffin, and a thin coating of tallow is sometimes smeared over afterwards, to preserve the varnish.

On another road, near the end of the shed, stands a powerful yet graceful-looking express passenger engine. Though not one of the company’s latest nor largest types she is one of the speediest with a train adapted to her power; and is of the “Atlantic” type, having a leading bogie, four wheels coupled (which are 6 ft 9 in diameter), and a pair of small trailing wheels under the firebox. She has a large boiler, really bigger than it looks, as it has a wide firebox; it carries a working pressure of 200 lb per sq in and delivers steam, superheated to about 600 degrees Fahr, to a pair of cylinders 20 in bore by 28 in stroke, with 10 in piston valves actuated by Walschaerts valve gear. The tender is a high-sided six-wheeler, carrying 4,000 gallons of water and six tons of coal; it has a water-pick-up apparatus. Many engines are known to the staff by a nickname, which is more easily remembered than a four-figure number, and this engine is known as “Winnie”. The district locomotive superintendent always endeavours to keep the same driver and fireman to one engine. He knows that it is the best way to keep maintenance costs at a minimum and to obtain the maximum efficiency from both men and machines. “Winnie” has, therefore, a regular driver and fireman.

Ready for the Run

The cleaners have finished with “Winnie”, there is nothing needed in the way of adjustments, and the boiler-filler has been along and seen that there is plenty of water showing in the gauge-glass. Had there not been, he would have filled her up with a hose connected to one of the shed hydrants, through one of the upper plugs on the boiler backhead. The firelighter next comes along with a long shovel full of live coal from the “sandhole”, or furnace where the sand is dried, puts this in the centre of the grate, throws in a few chunks of wood (usually broken-up sleepers), and some coal from the tender on top of that; he closes the fire-hole door and leaves the fire to burn up slowly. When the fire is not forced, boilers expand equally and do not suffer from leakage. “Winnie” stands quiescent until about 7 am, when she receives a visit from the man whose duty it is to see the engines are all ready for their booked turns.

WATER TROUGHS near Goring-on-Thames, Oxfordshire. Water is picked up by a scoop lowered from beneath the tender. Troughs are usually 18 in wide and 6 in deep, and usually extend for a quarter of a mile. They were first used in 1859.

He checks off “Winnie’s” time out, looks in the firebox and at the steam gauge, and ticks her off as in order. A few minutes before eight the fireman arrives; he has duly booked on at the time office on entering the depot. His first job is to look at the water gauge; he then puts his “tommy bag” and tea-bottle in the tender-box, puts on his overalls and levels up the fire in the box, puts some more coal on it, sweeps up the footplate, and has just started to crack up the coal on the tender when the driver arrives. Railway time-offices now use modern methods of clocking in; previously the driver would have called out the engine’s name and distinction as he passed the clerk. Driver and fireman exchange greetings; the driver picks up his oil bottles - they are called “bottles” though made of tin - and goes to the oil store, stopping to look at the notice-board in the office window or driver’s lobby. He also scans the report book to see if any small job booked up from last trip has been duly carried out and signed off. Returning to the engine, he fills his oil feeder and goes over every oiler in a systematic manner, at the same time examining the engine for any loose bolts, cracked parts or other defects. Meanwhile, the fireman has filled the sandboxes, attended to the lamps, and seen how much water is in the tender. Then they both take a look at the “Special Traffic” notice. This usually takes the form of a weekly journal issued to all railwaymen, recording any changes in signals or tracks, work being done on the line, alterations in timings, special traffic such as race-meeting trains, excursion trains, chalk and rock falling in cuttings, tunnel repairs, and so on.

Then at last “Winnie” starts to move as the driver gives her a little steam, which hisses loudly from the open cylinder cocks as she leaves the yard, and backs out on to the siding adjoining the sheds. The terminus is half a mile away; two sharp blasts on the whistle tell the signalman at the “Yard Junction Box” where she wants to go, so he sets the points for the “up local” road, pulls the signal, and “Winnie”, with an answering call, sets out for the terminus.

Then at last “Winnie” starts to move as the driver gives her a little steam, which hisses loudly from the open cylinder cocks as she leaves the yard, and backs out on to the siding adjoining the sheds. The terminus is half a mile away; two sharp blasts on the whistle tell the signalman at the “Yard Junction Box” where she wants to go, so he sets the points for the “up local” road, pulls the signal, and “Winnie”, with an answering call, sets out for the terminus.

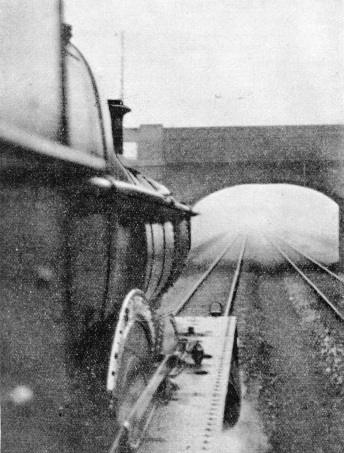

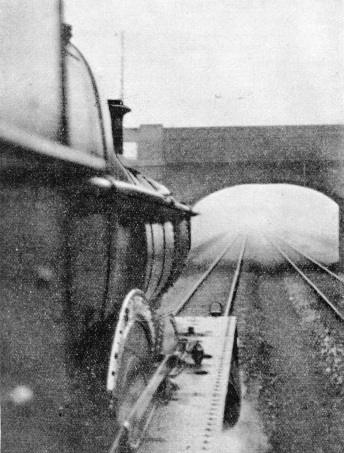

THESE STRIKING PICTURES were taken from the cab of an engine travelling at speed. They give a vivid impression of the driver’s outlook from the footplate.

For descriptive purposes, let us imagine a town called Seaville, a little over 120 miles from London. The road is fairly difficult; but at the urgent request of the Borough Council a two-hour non-stop service has been decided upon and duly scheduled. “Winnie” and her crew are making the first trip on the new timing. “Winnie” threads her way through the maze of points and crossings outside the terminus, and as she passes the last one at the end of No. 4 departure platform, the driver opens the trailing sander and sands the rails from that point to the train. The porter-shunter jumps down and catches the coupling-link. As the buffers of tender and first coach gently touch, he throws the link over the hook, screws up, and couples the brake hoses. The driver puts the brake-valve handle to “release” position, charging the train pipe, picks up his inevitable oil feeder and his running sheet, and steps on to the platform. Up comes the guard. He and the driver exchange a few words, and then the latter turns to give the locomotive a final drop or two of oil. He is watched with admiration by the usual crowd of small boys and grown-up locomotive enthusiasts who invariably come along to have a look at the engine. The guard says “fifteen on”, but there are ten bogie coaches on the train. Engine-men “reckon” a train in different ways; some go by the number of axles; in this instance a six-wheeled carriage counts one, an eight-wheeler one and a half, and a twelve-wheeler (such as a dining-car) two. Meanwhile the fireman has made up his fire and attended to the boiler-feed apparatus; the driver applies and releases brakes as a test; the guard also makes a test application from his van. Doors are slammed. The platform inspector presses a button on a lamp standard which tells the signalman all is ready. The colour-light signal on the end of the platform turns orange, then green; the guard waves his flag far back down the platform, the inspector blows his whistle. “Right away!” says the fireman, giving a tug at the whistle chain, and the driver pushes the regulator about a third open, the reverse lever being in full forward gear.

THESE STRIKING PICTURES were taken from the cab of an engine travelling at speed. They give a vivid impression of the driver’s outlook from the footplate.

The sniffing valve makes a smack as it closes, and “Winnie” gives a deep sigh as the steam rushes through the super-heater to the cylinders; a shiver passes through her steel body as she gives a mighty tug at the couplings, the big driving-wheels bite the sand, and the 350 tons of cars with their living cargo begin to move. Whup! Whup! Whup! comes in terrific staccato barks from her stubby little chimney as each cylinder discharges its spent steam up the blast-pipe. The platform slides away behind, the “green eye” on the signal-post approaches and disappears, and “Winnie” emerges from under the station roof into the sunshine of the early summer morning. As she bears to the left, making for the down main line, the driver looks back over the side of the cab; the guard from his van gives a wave, signifying “all clear”, and the race against time begins.

“Winnie” swings into the straight, rapidly accelerating, swaying gently as the mighty thrust from each big piston reacts through the cylinder to the frames. The driver “notches her up” a little; that is, he brings the reverse gear a little way back, which shortens the travel of the valves, and cuts off steam earlier in the stroke. When “Winnie” started she cut off at seventy-five per cent of the piston travel; now she is cutting off at forty-five per cent and the expansion of the steam is doing the rest. She is still accelerating, and the staccato barks are beginning to pound like a machine-gun, but they have quietened down, owing to the reduced exhaust pressure of the expanded steam. Meanwhile, the blast has pulled the fire into almost white-hot fierceness, and the safety-valves are blowing off. Now the fireman gets busy with his shovel, feeding the coal under the door, in each back corner, down the sides of the box and in the front corners, so that the fire is somewhat saucer-shaped. The fire must not be thick, or the engine will lose pressure; neither must it have any “holes” through which cold air could be drawn.

Gathering Speed

The water is beginning to sink in the gauge glass, so the fireman puts on the exhaust injector, which makes some of the exhaust steam that would otherwise be wasted do useful work in keeping the boiler supplied with water. Next he turns a jet of water from a small hose on the coal in the tender, wetting it down to prevent dust blowing about. The fireman hastily brushes a few stray nuggets of coal from the footplate back against the tender, then takes a breathing space and looks ahead.

The locomotive is now almost touching the mile-a-minute rate, and is travelling along through the southern outskirts of London, roaring over bridges that span busy main roads, flying past rows of suburban gardens, hurtling past her city-bound electric competitors, and giving a brief roar as she dives under an occasional stone over-bridge. Green lights flash up and disappear behind at regular intervals. The driver has notched up to a twenty-five per cent cut-off, and “Winnie’s” “bark” has quietened to a purr, the beats now being so rapid that they are almost indistinguishable. The driver has nothing to worry about so far as cylinder lubrication is concerned, as a mechanical lubricator up by the smoke-box is attending to that, and allows him to keep his attention on the signals. The fireman does not let the fire die down in the least, but as soon as the last load of coal is fully incandescent, and the safety-valves just “on the pop”, on goes more coal. He also looks after the injector, and keeps the water level near the top of the glass.

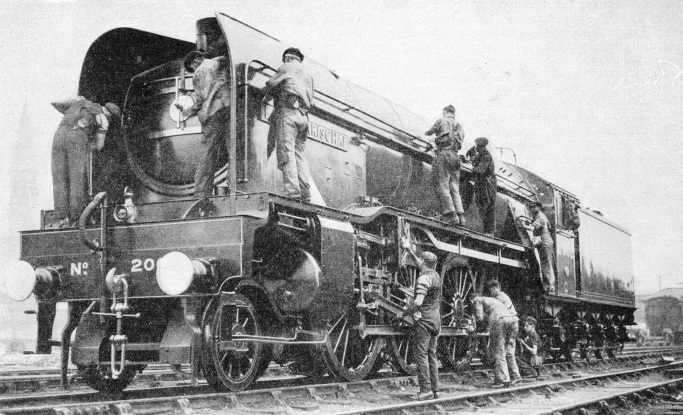

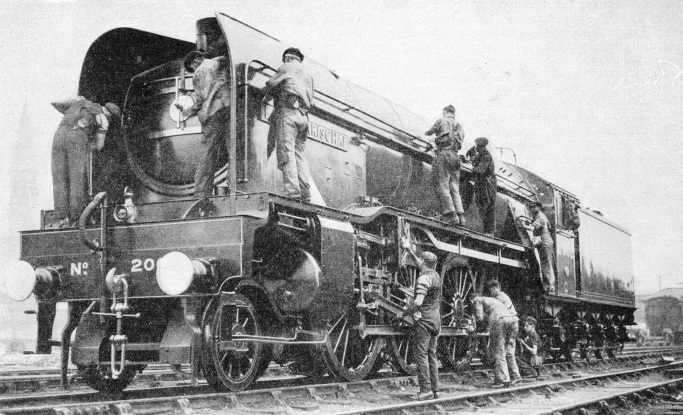

GETTING HER READY. Cleaners at work on the magnificent LNER engine, “Earl Marischal”. This locomotive is in the same class as the “Cock o’ the North”, but differs from that engine in its valve gear, which is of the piston-valve type. The “Cock o’ the North” has poppet valves.

Seventy! The engine swings round a long curve, and a busy junction comes into view, with several platforms and diverging sets of rails; two trains are standing there. A layman riding in the cab for the first time would experience a tremor. But the unwinking green eye among the cluster of red ones on the gantry that he passed a little way back has told the driver that all is clear, and with a long blast from her whistle the engine rushes through the junction. Her flying wheels rattle over the points. There is a confused blur of buildings and people, the junction drops behind, and the engine is in the open country. From now on semaphore signals take the place of colour-lights, and the fireman, glancing through the cab window on his side, sees the “distant” for the next section. It is down. “Off!” he calls to the driver, who responds. Whenever they are both looking out, if one sees a signal he “calls it” to the other.

The engine has now passed the eighty mark; but a blue line of hills has appeared in the distance, and the line and its banks rise. “Winnie’s” exhaust purr grows louder and she slackens speed slightly. The driver drops the lever a little and increases the cut-off, and opens the regulator wide, while the fireman keeps the injector going and feeds in more coal. Slower yet - the exhaust beats resume their staccato machine-gun bark; sparks and cinders fly from the chimney as “Winnie” puts her back into it and settles down to a steady drag up the bank.

She is still doing about forty-five miles an hour, but it seems slow after the previous high speed. Suddenly, the high walls of the cutting come to an abrupt dead end, and the black mouth of a tunnel appears ahead. “Winnie” plunges straight in. In a minute or so a bright speck appears in the darkness, rapidly grows larger, and with a roar and a rush “Winnie” shoots from the tunnel. The summit of the bank was in the tunnel, and the engine is now rapidly regathering her lost speed. The driver notches up again, while the fireman wipes his brow and takes a drink from his tea-bottle. He glances at the driver inquiringly. The driver looks at his watch and holds two fingers downward, thereby signifying two minutes behind on the new schedule. The fireman smiles and nods in the direction of the steam gauge, the needle of which is just on the 200. There is a slight down-grade here, and the driver gives “Winnie” her head, with the regulator wide open and the cut-off notched up to about twenty per cent. Up goes the speed - seventy - eighty - ninety - through a country junction with the wheels sounding like the beating of a kettledrum.

If the “distant” signal (with yellow face and swallow-tailed arm) at the beginning of a section is “off”, that section is clear right through. The signalman does not drop the “distant” until he has received the “all clear” from the next box ahead, and has pulled off the home and starting signals. As the fireman watches for the “distants”, he calls them, and if they are “off”

he shovels hard. If one were “on” (at danger) he would not put any coal on the fire, but would drop the damper and open the door a little; the driver would put the blower on, to prevent flames blowing back from the firehole as he shut the regulator and prepared to stop at the home signal if still at danger when he reached it; the safety-valves would, of course, blow off furiously.

Ahead lie the track water troughs, where the locomotive takes a running drink; the fireman lowers the scoop under the tender by means of a little handle (it is air-operated) and it dips into the quarter-mile-long trough; the water rushes up and fills the tank.

Presently a salt tang in the air becomes discernible; two tracks broaden into four, houses appear on either side. The fireman ceases to shovel, the driver shuts off steam and lets “Winnie” coast. He moves his brake-valve handle to “service stop” position, and eases the speed to twenty miles per hour as they approach the Seaville terminus, and then releases the brakes. “Winnie” slows down gently of her own accord; a green light on the signal-gantry with a number on a disk underneath it, tells the driver that No. 9 platform is waiting for him. “Winnie” noses over the points and crossings and turns into the platform road. When about half way along, the driver makes another service application of the brake, and “Winnie” finally comes to rest with her buffers a yard or so from the hydraulic buffer stops at the end of the platform. The big clock over the station concourse indicates 11 am - “Winnie” has arrived on time.

IN THE ENGINE SHED at Willesden, London, these LMS locomotives present an impressive picture. The large cowl-like box above each smoke stack is known as a “flue”, and serves to keep the shed free from smoke.

You can read more on “Cleaning a Giant Locomotive”, “How Engines Pick Up Water” and “Locomotive Accessories” on this website.

Then at last “Winnie” starts to move as the driver gives her a little steam, which hisses loudly from the open cylinder cocks as she leaves the yard, and backs out on to the siding adjoining the sheds. The terminus is half a mile away; two sharp blasts on the whistle tell the signalman at the “Yard Junction Box” where she wants to go, so he sets the points for the “up local” road, pulls the signal, and “Winnie”, with an answering call, sets out for the terminus.

Then at last “Winnie” starts to move as the driver gives her a little steam, which hisses loudly from the open cylinder cocks as she leaves the yard, and backs out on to the siding adjoining the sheds. The terminus is half a mile away; two sharp blasts on the whistle tell the signalman at the “Yard Junction Box” where she wants to go, so he sets the points for the “up local” road, pulls the signal, and “Winnie”, with an answering call, sets out for the terminus.