A New and Novel Articulated Locomotive

An ingeniously constructed engine which may mark a new era in locomotive design

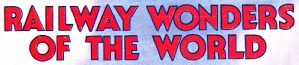

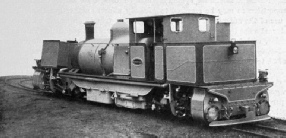

THE “GARRATT’’ PATENT LOCOMOTIVE, used on the Tasmanian Government Railways’ north-

DURING the past few years the increasing demands for greater power to haul heavier and longer trains has been responsible for the display of striking ingenuity in connection with locomotive design.

Recently the attention of engineers and others concerned with the economical operation of the great railways of the world has been attracted to quite a new and novel type of steam railway engine, which has been evolved by a British inventor, Mr. H. W. Garratt, M.I.Mech.E., and the question has been discussed as to whether it does not indicate a new era in locomotive design. Although it belongs essentially to the articulated class, it has one great advantage over its prototypes -

It is conceded generally that inventors have very little scope for further development within the recognised limits of loco-

The questions of weight distribution and a large grate area of proper proportions also influence the situation very materially. Locomotive engineers have surmounted these various handicaps by lengthening the boiler and increasing the number of driving wheels, but this has given birth to another objection. It is useless to extend the length of the boiler without enlarging the grate area of the fire-

In these circumstances the problem which Mr. Garratt sought to solve was necessarily of a complex and searching character. In order to achieve any measure of commercial success it was necessary to depart from conventional lines. In this quest, however, he has succeeded, and his efforts culminated in the production of a design which is distinctly novel, ingenious, effective and economical in working. When he had completed his ideas he submitted them to one of the foremost British locomotive building organisations, Messrs. Beyer Peacock and Company, Limited, of Gorton Foundry, Manchester. They readily appreciated the outstanding features of the new system, acquired the patents, and undertook to exploit the invention. Several months were expended upon the perfection of the details of the designer’s handiwork. The first opportunity to ascertain the possibilities of the system came when the chief engineer of the Tasmanian Government railways suggested that small engines of this class should he given a practical test upon the State system of the island.

This was about as severe a test as could be conceived for a new idea. The locomotives were required for working upon the North East Dundas section of the State system, where the gauge is 2 feet, with grades running up to 1 in 25, and with curves of 99 feet radius. Rigid stipulations were laid down to which the engine had to conform, so that it cannot be said that the inventor was given the opportunity to demonstrate his ideas under the (to him) most favourable conditions. Two locomotives were built and shipped to Tasmania in 1909, where they have been running continuously ever since.

The salient feature wherein the Garratt locomotive differs from its contemporaries is that the boiler is a distinct unit, and is not mounted above the driving wheels in the usual way. Fundamentally it comprises three sections: the boiler with its firebox, and two end bogies, each of which is a driving unit, so that it may be described as a boiler and two complete motor bogies, one placed at each end, as the latter carry the cylinders, pistons, and driving gear. The boiler, including fire-

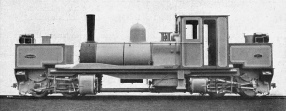

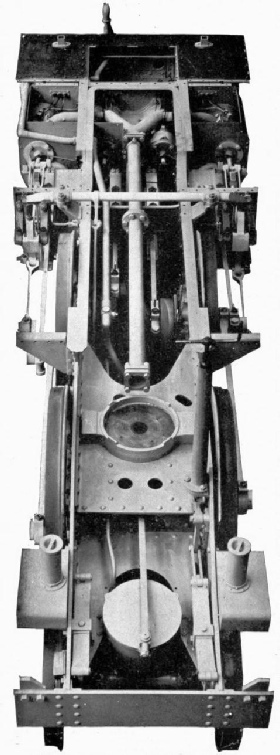

UNITS OF THE EIGHT-

The two end bogies, in addition to carrying the driving mechanism, are also utilised for the bunkering of the coal and water, so that a tender in the usual sense of the word is rendered unnecessary. The weight thus imposed not only increases the adhesion of the wheels, but when the locomotive is running at high speed, they effectively assist to prevent oscillation of the bogies, so that the wear and tear upon the flanges of the wheels, and. also the rails, is reduced to a minimum. The capacity of the tanks may be varied according to requirements, this factor being governed entirely by the number of wheels to the bogie and the axle-

In the case of simple expansion working, the steam from the boiler is taken from the dome by means of two regulators with piping, one of which extends to the smoke-

By dividing the locomotive into three parts in this manner the full effects of articulation are obtained. Owing to the rigid section, that of the boiler and its frame, being kept as short as possible, and the two bogies having free play, the sharpest curves and inequalities in the track may be negotiated with extreme ease, and the flexibility is such that the whole engine conforms with natural freedom to the curve. In rounding a curve, the rigid central section forms a true chord of the arc, while the sharper the curve the more the centre of gravity is brought inwards, so that exceptional stability is secured. The extreme flexibility of this type of engine is demonstrated most convincingly, possibly, on sharp reverse curves, which may be rounded at high speed with far greater safety than is possible with the ordinary locomotive, there being an entire absence of stiffness or grinding of the flanges against the rails. There is none of that climbing tendency of the engine which often is experienced under such conditions, and which has been responsible for many derailments. Another point which cannot fail to be observed is that there is no overhang of the boiler frame when rounding a curve, as the articulating centres are fixed at the extreme ends of this frame. This contrasts very vividly with the overhang of the boiler and frame upon the general type of semi-

It might be thought that difficulty would arise in distributing the loads uniformly over the axles, especially as the weight of the fuel and water is fluctuating constantly; but with efficient designing this is not so. The combined weight of the fuel and water represent such a small proportion of the total weight of the bogies that even if the whole of these commodities were consumed -

In the first engines of this type, built for Tasmania, there is a small bogie at either end, fitted with two coupled axles; compounding was stipulated, although it is not essential to the Garratt system, and its incorporation involved somewhat heavy and unavoidable complications. The high-

LOOKING DOWN ON AN ENGINE UNIT OF A GARRATT LOCOMOTIVE.

When the Tasmanian engines appeared they aroused considerable interest, but were regarded in many railway quarters as a novelty, comparable with the Fontaine and other unusual designs which have appeared from time to time. But the experience gained on the Tasmanian railways tends to indicate that the engines are eminently adapted to peculiar conditions, While inquiries concerning the adaptability of the idea to other countries commenced to roll in, the system received its complete vindication when the Tas-

In Tasmania the railway situation has developed, as it has in other countries. Increased weights had to be handled by the engines. The adoption of corridor coaches in the express passenger service doubled the weight of the train to be handled by the existing locomotives, and, in combination with high speed, the ordinary type of engine was ruled out of court upon the 8 feet 6 inch gauge with grades of 1 in 40 and curves of 330 feet radius. The axle-

The situation has been met completely by a Garratt simple locomotive, having two groups of four-

So far as the goods locomotives are concerned, the same governing factors, except high speed and axle-

The absence of side tanks and of wheels below the boiler -

In the Garratt locomotive the power or tractive effort is governed solely by the permissible load per axle, and the number of coupled axles, since in this type the boiler can be made so large as to be capable of supplying sufficient steam for cylinders of such proportions as may be required to make full use of the adhesive weight. For instance, for standard gauge working, a Garratt engine, with two six-

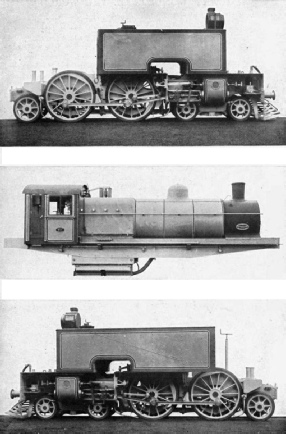

A GARRATT LOCOMOTIVE FOR THE DARJEELING-

Up to the present engines of this design have not been adopted for working upon standard gauge railways, but owing to the success of the engine upon narrower gauges, combined with its great possibilities, the day doubtless is approaching when it will be taken up for such work. It may not be seen for some time in this country, since the problem of the railway loco-

Railway operators cannot fail to appreciate other advantages which the system offers, and which tend towards highly economical working. The design and arrangement conduce to easy riding, so that the track is given a longer lease of life, while the engine itself is spared those severe racking strains and stresses inseparable from the conventional articulated locomotive. It forms a perfect double-

The ease with which overhaul and cleaning operations can be carried out must not be overlooked. Owing to the fire-

EIGHT-

You can read more on

“Giant American Locomotives” and

on this website.