Their Evolution and Advantages

LOCOMOTIVES - 25

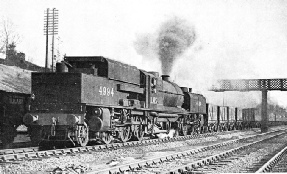

A FORMER “ATLANTIC” TYPE express engine of the North Eastern Railway, as rebuilt by the LNER, with booster-driven trailing bogie partly under the tender. The auxiliary two-cylinder booster engine can be employed or cut out at will. The locomotive is therefore of the “temporarily articulated” type. This is one of the few locomotives whose wheel arrangement cannot be described by the standard system.

A FORMER “ATLANTIC” TYPE express engine of the North Eastern Railway, as rebuilt by the LNER, with booster-driven trailing bogie partly under the tender. The auxiliary two-cylinder booster engine can be employed or cut out at will. The locomotive is therefore of the “temporarily articulated” type. This is one of the few locomotives whose wheel arrangement cannot be described by the standard system.

AN articulated locomotive is a locomotive having one or more of its driven axles capable of taking up positions in which they do not remain parallel to the others, so that they assume angular positions when rounding curves. There are few articulated engines in Great Britain, and the outstanding part they play in the operation of the world's railways is not always realized in that country.

Although the articulated locomotive has been used on subsidiary and mountain lines since the earliest times of railways - it was invented in 1830 by Horatio Allen, the American engineer - its widespread adoption for main-line traffic on important railways belongs largely to the twentieth century.

To appreciate the merits of the articulated steam locomotive, there must first be understood the difficulties which attend the employment of very large non-articulated engines - that is, engines with all driving wheels coupled together and rigidly attached to the main frames. To obtain sufficient power to meet traffic requirements abroad with a rigid machine - the term “rigid” applies to driving wheels only, and not to leading or trailing wheels - the engine weight has exceeded twenty-five tons per axle in certain instances. With a ten-coupled engine this means a weight of more than 250 tons bearing upon approximately 17 ft of track. Bridges are often insufficiently strong to accommodate such an engine as this, and so require rebuilding. Permanent way may also have to be relaid throughout with heavier rail. In addition to the immediate expense entailed, the heavier rail will raise the cost of replacement as the track wears out.

Another disadvantage of large rigid locomotives, especially freight engines which have many wheels coupled, is their inability to round sharp curves. Only a fractional amount of side play can be arranged for the driving wheels of a rigid engine, and it follows that only very gentle curves can be negotiated by engines with more than eight wheels coupled. This drawback is emphasized by the fact that railways in mountainous country, where powerful locomotives are required to climb the gradients, are the very railways where sharp curves are likely to be found.

Flexibility on Curves

To overcome these difficulties the articulated locomotive has been introduced. Subsidiary advantages of the different articulated designs will come to light as the various types are discussed.

The axles of an articulated locomotive are arranged in groups, each group being spoken of as a “truck”. This may support part of a rigid main frame, or a mobile frame which is integral with the truck. The truck can move radially around a real or a virtual pivot. When the pivot is situated at a point inside the truck, the truck is called a “bogie”. When it is placed outside to the rear or fore, the truck is called a “bissel”. Only one type of articulated locomotive has been used for important services in Britain. This type is known as the “Beyer-Garratt”. Messrs. Beyer, Peacock & Co, Ltd, of Manchester, are the sole patentees of this type of engine, though permission has at times been granted for other firms to construct the design.

The “Beyer-Garratt” consists, virtually, of two ordinary locomotive chassis, placed some distance apart, and held together by a girder frame which supports the boiler and firebox. The weight of boiler and frame is transmitted to the two chassis by means of pivots at either end, and this enables the engine to swing round sharp curves with ease despite the great overall length. Coal and water are stored in containers at either end, carried on mobile frames, integral with the trucks. The coal bunker is so arranged that there is ample vision through the rear cab windows, and thus the “Beyer-Garratt”, in the same way as the tank engine proper, can travel in either direction with equal facility.

The extended distance over which the weight of the engine is distributed enables the “Beyer-Garratt” to work over far lighter track than the large rigid engine. This will be understood from a comparison between a typical heavy rigid engine of the 2-10-2 type, affording, say, 70,000 lb tractive effort, and a 4-8-0 + 0-8-4 type “Beyer-Garratt” of the same power. The term “4-8-0 + 0-8-4” signifies the use of four leading wheels, eight coupled driving wheels, with no trailing wheels to follow, this completing the front truck of the articulated engine; the rear truck is the same again, but arranged the other way round, so that the two trucks - always of corresponding wheel formula in the “Garratt” design - stand essentially back to back. The code may be conveniently shortened to 4-8 + 8-4.

A 2-10-2 type locomotive of the power stated exerts a weight of approximately twenty-eight tons per coupled axle upon the track, and requires a rail as heavy as 115 lb per yard to take the strain. With the 4-8-0 + 0-8-4 “Beyer-Garratt”, however, the weight carried by the two separate groups of driving wheels is no higher than twenty tons per axle, and this allows the use of rails weighing 90 lb per yard. The rigid 2-10-2 requires eighty-three more tons of rails and sleepers per mile of single track than the “Beyer-Garratt”. The heavier rail costs £700 per mile more than the lighter type, plus extra maintenance costs. A further advantage of the “Garratt”, arising from its low-slung boiler, is that it can pass a smaller loading gauge than the rigid engine.

Sixteen “Beyer-Garratt” locomotives of the 4-8-0 + 0-8-4 type are in service on the 5 ft 6-in gauge lines of the Bengal Nagpur Railway in India. They have shown their ability to handle loads of 2,000 tons on grades of 1 in 100 at 15 mph, compared with previous loads of 1,650 tons hauled at 8 mph by two ordinary steam locomotives. The resulting economy in coal consumption proves to be 28 per cent. With a tractive effort, at 85 per cent boiler pressure, of 70,000 lb, the Bengal Nagpur “Garratts” rank as the most powerful engines in India.

Pioneer “Beyer-Garratts”

Nearly all “Beyer-Garratt” locomotives are arranged for simple expansion, the steam being conveyed from the boiler to the two engine units - each of which has two, three, or, occasionally, four cylinders - and back to the smoke-box by means of flexible pipes. The first “Beyer-Garratts” built were, however, arranged on the dual-expansion or compound system. They were supplied for 2-ft gauge lines operated by the Tasmanian Government Railways. They had the 0-4-0 + 0-4-0 wheel arrangement, and were provided with four cylinders.

Since these pioneer “Garratts”, turned out in 1909, the type has spread to many parts of the world. It is now found in Spain, Madagascar, Mauritius, South America, Ceylon, Burma, India, Turkey, Russia, West Australia, Victoria, New Zealand, Tasmania, Great Britain, and many parts of Africa. The “Beyer-Garratt” is specially popular on 3 ft 6-in and narrow-gauge lines, where the restricted loading gauge forbids the use of very large and powerful boilers on ordinary engines.

It might be thought that the tortuous nature of many 2-ft gauge lines, where sharp reverse curves follow one another without intermediate lengths of straight, and, similarly, up grades follow down grades without any level portions between, would present impossible conditions for an engine of such length as the “Beyer-Garratt”. But practice has shown that adequate flexibility can be afforded on “Garratt” principles. In addition to the simple turning movement, the two bogies can be inclined in opposite directions at the same time to suit the banking of reverse curves, and they can be tipped upwards or downwards in opposing planes when traversing dips or summits in the line.

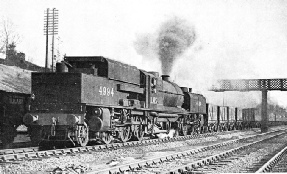

MODERN “BEYER-GARRATT” articulated engine of the 2-6-0 + 0-6-2 type, hauling a coal train on the LMS line. “Beyer-Garratt” locomotives are used for handling the heavy mineral traffic between the Nottinghamshire coalfields and the marshalling sidings at Cricklewood, London, over the Midland route. Thirty-three of these efficient locomotives have been built for the LMS since 1927.

Apart from a small 0-4-0 + 0-4-0 engine built in 1923 for the standard gauge track of the Hafod Copper Works, near Swansea, the first “Beyer-Garratt” to appear in service in Britain was supplied by Messrs. Beyer, Peacock to the LNER in 1925. For ten years this locomotive has remained the most powerful engine in the British Isles. It is a six-cylinder 2-8-0 + 0-8-2 type, and is used for assisting coal trains over a difficult seven-miles stretch of line between Wath and Penistone, which has a gradient of 1 in 40 for two miles. The tractive force, at 85 per cent of the boiler pressure, is 72,940 lb. The LNER “Garratt” does the work of two ordinary 2-8-0 engines previously employed, and since it cost less to build, is less clumsy, and burns less fuel than the other two engines put together, and also needs only two men to operate it instead of four, the economies to be derived from its employment are rightly held to be far reaching. The LMS introduced a smaller 2-6-0 + 0-6-2 type “Beyer-Garratt” for service on its Midland Division in 1927. Thirty-three of these valuable engines are now at work, and they daily haul 1,450-ton coal trains at overall speeds of 21 mph for distances of more than a hundred miles. With a hundred empty wagons they can attain 50 mph. Apart from these LMS and LNER examples, there are no “Beyer-Garratt” engines at present operating on mainline railways in the British Isles.

The majority of “Beyer-Garratts” are employed either as goods or as mixed-traffic engines, but their possibilities for high-speed passenger work have recently been revealed. Well-known express “Garratts” are the six engines of the 4-6-2 + 2-6-4 or “Double Pacific” type used on the 5 ft 3 in gauge São Paulo Railway of Brazil. One of these “Double Pacifics”, which have 5 ft 6 in driving wheels, ran over 7,500 miles in one month, at an average running speed of 40 mph, and with an average load of 500 tons. The maximum gradient encountered was 1 in 40.

Fast runs have been made by “Beyer-Garratt” locomotives in Tasmania, where the Government Railways introduced some eight-cylinder, simple-expansion engines for their 3 ft 6 in gauge lines in 1912. With the “Double Atlantic”, or 4-4-2 + 2-4-4, wheel arrangement, these express engines have attained speeds up to 60 mph between Launceston and Deloraine - a remarkable achievement for an articulated locomotive on a gauge so moderate as this. Curiously enough, the highest speed ever recorded behind a “Beyer-Garratt” has been in Africa, where high speed is generally impossible. The record was made over the important French Colonial lines operated by the Paris, Lyons and Mediterranean Railway in Algeria, where four 4-8-2 + 2-8-4 “Garratts”, for the 3 ft 6 in gauge, and one express 4-6-2 + 2-6-4, for the standard 4 ft 8½-in gauge, were introduced in 1932-3.

The express engine has the largest driving wheels ever seen on an articulated locomotive. They are 5 ft 11-in in diameter. During exhaustive tests, made over the Algiers-Oran main line, in 1933, the engine showed remarkable hill-climbing capacity, and proved its ability to haul 639 tons at 65 mph on the level. Despite the great length of the articulated engine, smooth running, without a trace of rolling, was obtained at this high speed. The greatest speed attained, made with a special light train of 118 tons, took place down a grade averaging 1 in 916, with the engine travelling chimney rearmost, and the maximum figure reached was 81½ mph - not only a record for an articulated locomotive, but also almost certainly the highest speed ever attained in the African continent.

An interesting experimental “Beyer-Garratt” was transhipped from Manchester to Russia at the end of 1932. In this locomotive Messrs. Beyer, Peacock combined Russian, American, and British practice, and the engine was the largest ever built in Europe. Designed for the standard Russian rail gauge of 5 ft, it has a total weight in working order of 255 tons, a length of a little over 100 ft, a grate area of 86 sq ft, a height from rail to chimney of 17 ft 2 in, and a tractive effort of more than 70,000 lb. The engine is of the 4-8-2 + 2-8-4 “Double Mountain” type.

Although of smaller proportions, a class of “Double Mountains” introduced to the South African Railways in 1929 has even greater power than the Russian engine. Each of these engines, of which there are eight, exerts a tractive force of all but 90,000 lb at eighty-five per cent boiler pressure. They run on a gauge of only 3 ft 6 in, yet they are the most powerful locomotives in the world outside the North American continent. They carry a huge boiler of 7 ft 3⅜-in outside diameter - more than twice the width of the rail gauge. The engines are successfully hauling loads of 1,000 tons on the up grade and 2,000 tons on the down grade on the Durban-Cato Ridge section, Natal. The steepest banks are graded at 1 in 65.

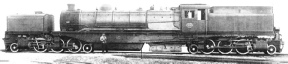

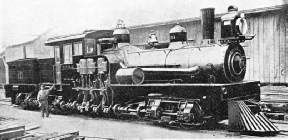

BUILT IN GERMANY. This “Union-Garratt” articulated locomotive was supplied by Messrs Maffei, Munich, to the South African Railways in 1927. Special features, in contrast with the “Beyer-Garratt”, are the extended girder frames which unite the coal bunker and rear tank with the boiler, and the extra well tank in front of which the man is standing. The total length of the locomotive is 74 ft 8 in, and the service weight is 164 tons 16 cwt. The diameter of the driving wheels is 4 ft, and the boiler pressure 180 lb per sq in. This engine is of the 2-6-2 + 2-6-2 type. The gauge is 3 ft 6 in. Tractive effort is 75 per cent of the boiler pressure is 50,050 lb. The cylinders measure 18½ in by 26 in.

In 1927 and 1928 the German firm of Maffei, in co-operation with Beyer, Peacock, supplied to the South African Railway some 2-6-2 + 2-6-2 and 4-6-2 + 2-6-4 “Garratt” engines of a new type. The modified engines, known as the “Union-Garratt” type, had the girder frame which supports the boiler extended backwards so as to carry the rear water tank and the coal bunker. This enabled automatic stokers to be used, because of the rigidity of the bunker with relation to the firebox. Orthodox “Beyer-Garratts”, including the Russian and South African “Double Mountains” already cited, have now been successfully adapted for mechanical stoking.

In the “Union-Garratt” design the main frame is secured by a three-point suspension. There is a pivot in front, as with the “Beyer-Garratt”, but the suspension behind is by means of two side brackets. A longer boiler is a feature of the “Union-Garratt”, and this calls for a reduction in the size of the leading water tank. The balance of the water supply is made up by a well tank provided under the boiler.

A disadvantage of the “Union-Garratt”, in comparison with the “Beyer-Garratt”, is that the fuel and water tanks carried on the rear bogie cannot follow the bogie's angular motion when rounding curves, so that their weight is not symmetrically distributed through the side brackets to the wheels.

It is curious that the “Garratt” type of engine, although so popular in other parts of the world, is nowhere found, in the North American continent. In view of the enormous size of locomotives suitable for hauling American and Canadian train loads, articulation of some sort has been found necessary.

“Mallet” Locomotives

In the year 1885 Anatole Mallet, the eminent French engineer, patented the type of articulated locomotive which has been built in many hundreds in America during the present century. The “Mallet” patent locomotive is also used in Europe, Africa, India, Burma, Siberia, Java, China, Japan, South America, and elsewhere.

In the “Mallet” design there are two sets of driving wheels, each with the necessary cylinders, valve-gear, and so on. The rear set is an integral part of the locomotive, as in a rigid engine, while the leading set constitutes a bissel truck. The centre of rotation of the truck is located in front of the rear group of wheels between the rear cylinders. It will be seen that the “Mallet” is really only a semi-articulated engine, since the driving wheels are not all flexible.

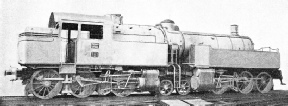

A MODERN EXAMPLE of the “Mallet” type of semi-articulated locomotive. It is used on the metre-gauge Burma Railways, and has the 0-6-0 + 0-6-0 wheel arrangement. The working steam pressure is 180 lb per sq in, total heating surface 1,442 sq ft, and the diameter of the driving wheels 3 ft 3 in. There are two 15½ in diameter high-pressure cylinders, and two 24¼ in low pressure cylinders, with a common piston stroke of 20 in. The tractive force at 50 per cent of the boiler pressure is 22,170 lb, and the service weight of the engine and tender is 95¾ tons.

A MODERN EXAMPLE of the “Mallet” type of semi-articulated locomotive. It is used on the metre-gauge Burma Railways, and has the 0-6-0 + 0-6-0 wheel arrangement. The working steam pressure is 180 lb per sq in, total heating surface 1,442 sq ft, and the diameter of the driving wheels 3 ft 3 in. There are two 15½ in diameter high-pressure cylinders, and two 24¼ in low pressure cylinders, with a common piston stroke of 20 in. The tractive force at 50 per cent of the boiler pressure is 22,170 lb, and the service weight of the engine and tender is 95¾ tons.

The “Mallet” differs from the “Garratt” in that it does not always have a corresponding wheel formula for both sets of wheels. Such unusual arrangements as 4-4-0 + 0-6-2 and 2-6-0 + 0-8-0 have thus been used at times. “Mallet” locomotives are mostly tender engines, though some tank engines have been built for the smaller railways.

In the matter of speed, the “Mallet” does not compare favourably with the “Garratt”, nor with other completely articulated types. Because of the rigid set of driving wheels at the rear, the enormous boiler and frames of the “Mallet” are directly subjected to any shocks due to inequalities in the road bed; it is this feature which generally makes “Mallets” unsafe at speeds above 30 mph. The abnormally long boiler is more of a disadvantage than an advantage. The short, large diameter boiler of the “Garratt”, with very deep, square-bottomed firebox, gives superior evaporative capacity, and is easier for firing.

There is, on the other hand, or there certainly was, an outstanding advantage in the “Mallet” semi-articulated design. The flexible steam pipes necessary with an articulated engine are susceptible to leakage when steam at high pressure is passed through them. It has therefore - until recently - been found difficult to obtain high tractive power within the limits in steam pressure allowed by the piping. Anatole Mallet here secured an advantage. Because of the rigidity of the rear pair of cylinders in his design, he was able to use high-pressure steam, which was afterwards allowed to pass at reduced pressure through flexible pipes to the forward and larger pair of cylinders attached to the bissel truck. In other words, Anatole Mallet made use of the dual-expansion or compound system - the system which he himself first successfully applied to a railway locomotive in France in 1877.

During the past decade such strides have been made in the design of ball-and-socket and sliding joints in steam pipes that high-pressure steam can now be passed without difficulty. In consequence of this perfection of flexible steam piping, the “Mallet” locomotive has lost a former advantage over the fully articulated type. It has, at the same time, shared with other articulated engines the benefits of this improvement in design and “Mallets” carrying high-pressure steam in all cylinders are now becoming common. The successful new piping will also prevent such tedious experiments as were made, for example, by Mr. Johnstone, the American engineer, in 1885. To avoid the use of flexible steam pipes, Mr. Johnstone produced a modified type of double-end “Fairlie” engine, in which the cylinders were securely attached to the main frames, while the wheel trucks rotated as in an ordinary articulated engine. The extraordinarily complicated arrangement of valve-gear and connecting rods necessary to make the engine function can well be imagined.

The “Mallet” semi-articulated type has been found valuable on railways varying from 5 ft 6-in to 1 ft 1½-in in gauge. The United States have turned out by far the greatest number of “Mallets” and the largest examples of this type of locomotive. American engineers have even made experiments with “Mallets” having separable and articulated boilers, the latter being ingeniously arranged on the concertina principle for a space of a few feet in the middle.

The largest steam locomotives in the world, at the time of writing, are of the “Mallet” type, and are used for hauling freight trains over the 1 in 91 grades between Mandan (North Dakota) and Glendive (Montana), 216 miles, on the Northern Pacific Railway. They have the 2-8-0 + 0-8-4 wheel arrangement, and weigh, with tender, 498¼ tons in running order. There are four high-pressure cylinders, taking steam from a boiler pressed at 250 lb per sq in. An illustration of the type appears on page 137 of this work.

Particularly interesting are the “Mallets” of the "triplex" type, first used on the Erie Railroad in 1914. Three engines were set to work during the early years of the war of 1914-18, one of them being named “Matt H. Shay”, after a famous “Erie” engine driver. In these engines there are three sets of driving wheels instead of two, as in the standard “Mallet”. The wheel formula is 2-8-0 + 0-8-0 + 0-8-2, a pseudo-tender forming an integral part of the rear truck. The middle set of driving wheels is rigid, while the outer sets are of the customary bissel type. The weight in working order is 383 tons 13 cwt, the overall length 106 ft, and the estimated tractive force 160,000 lb.

THE FAMOUS TRIPLEX “MALLET”, “Matt H. Shay”, of the Erie Railroad, USA. Once the largest locomotive in the world, this engine of the 2-8-0 + 0-8-0 + 0-8-2 type, can haul loaded freight trains over a mile long. The diameter of the six cylinders is 36 in and exceeds the length of the piston stroke, which is 32 in. The rear pair of cylinders exhausts into an auxiliary chimney, seen at the back of the pseudo-tender.

The “Erie” triplexes were designed for banking freight trains up the 1 in 67 Susquehanna incline in Pennsylvania. Each takes the place of three ordinary locomotives previously used as pushers. In trials made over a more level stretch of line, an “Erie” triplex drew a freight train of 250 loaded wagons, their total weight, excluding the locomotive, amounting to no less than 16,025 tons. Pusher engines were used at starting, to avoid excessive stress on the draw-gear. The triplex eventually attained a speed of 13½ mph. The train was over a mile and an eighth in length, and is believed to have been the longest and heaviest train ever hauled by one locomotive at any time in the history of railways.

Similar triplex “Mallets” were built for the heavy coal traffic running over the Virginian Railroad. The provision of a trailing four-wheeled bogie, however, makes these of the 2-8-0 + 0-8-0 + 0-8-4 type. All the triplexes have six outside cylinders arranged in pairs, and are designed for compound working, though alteration to simple-expansion working can be made at will. This obtains with many compounds. The centre pair of cylinders in the triplex takes the high-pressure steam, while the outer pairs take the low-pressure, the exhausted steam from the rear pair passing up through a feed-water-heater in the tender to an auxiliary chimney at the rear.

Certain giant 2-10-0 + 0-10-2 tender “Mallets”, used on the Virginian Railroad in company with the triplexes, were built in 1918. These four-cylinder compounds, when starting from rest under simple expansion, exert the amazing tractive force of 176,000 lb. They are among the most powerful steam locomotives in the world. Although less complicated than the triplexes, they have the disadvantage, from the standpoint of track maintenance, of a great weight of 27 tons 11 cwt carried on each driving axle. The heaviest train ever hauled by one of these locomotives was a coal train of 15,400 tons, a mile and an eighth long. After some rear-end assistance at starting and over preliminary gradients, the “Mallet” hauled the train unassisted 125 miles from Victoria to Sewall’s Point, Virginia.

The “du Bousquet” type of articulated tank locomotive, first used on the Northern Railway of France in 1905, somewhat resembles the “Mallet”. In the “du Bousquet” design there are two driven trucks, supporting a rigid frame on which the boiler, cab, and accessories are mounted. The front bogie can move in any direction with relation to the boiler, while the rear bogie is free to turn only about a horizontal axis. The water is carried in four long side-tanks, while the coal occupies an ordinary bunker. In contrast to the “Mallet”, which normally has each pair of cylinders placed to the fore of each wheel group, the four cylinders of the “du Bousquet” are bunched together opposite one another at the centre of the locomotive. This has the desirable effect of reducing the length of flexible steam piping necessary to connect high-pressure and low-pressure cylinders – “du Bousquets” are all of the compound type.

Application to Tanks

These articulated tanks are not popular at the present day, partly because of the high power nowadays successfully developed in engines with a wheelbase not too long to be rigid. Some of the original “du Bousquet” designs built between 1905-11, however, are still giving useful service. They are all of the 0-6-2 + 2-6-0 type, and are closely similar. They were introduced on the Nord, Est, and Grande Ceinture Railways of France, and on the Pekin-Hankow Railway of China, these being of standard gauge. Others were ordered for the 5 ft 6 in gauge Andalusian Railways in the south of Spain.

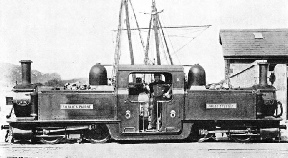

A POWERFUL TANK ENGINE of the 0-6-2 + 2-6-0 “du Bousquet” articulated type. There are two rear high-pressure cylinders, and two forward low-pressure cylinders, placed back to back. The driving wheels are 4 ft 5-in in diameter. The tractive force is 45,050 lb when working compound, and 49,170 lb when working simple. This unusual engine works on the standard gauge Pekin-Hankow Railway, China, and was built in Belgium in 1906.

A POWERFUL TANK ENGINE of the 0-6-2 + 2-6-0 “du Bousquet” articulated type. There are two rear high-pressure cylinders, and two forward low-pressure cylinders, placed back to back. The driving wheels are 4 ft 5-in in diameter. The tractive force is 45,050 lb when working compound, and 49,170 lb when working simple. This unusual engine works on the standard gauge Pekin-Hankow Railway, China, and was built in Belgium in 1906.

The primary intention of M. du Bousquet was to provide an engine capable of dealing with the heavy coal trains travelling to the east of France from the collieries of the north. The steepest banks met are graded at 1 in 83½. Forty-eight of the special tanks were built for this work at the Northern Company’s own shops, and they have shown their ability to haul 950-ton coal trains at 37 mph - thus showing the superior speed of the “du Bousquet” as compared with the semi-articulated “Mallet”.

“Mallets” and “du Bousquets” are not found in Britain, but the “Fairlie” type, already alluded to, has occasionally been employed there. The “Fairlie” articulated engine has been in use since 1865, and a number of variations of the original pattern are now found. There are three main “Fairlie” types: single-boilered engine, with one driven and one undriven bogie, or, rarely, two driven bogies; dual-boilered engine, with two fireboxes and two driven bogies; double-boilered engine, with one firebox and two driven bogies. In all examples the main frames are rigid from end to end, and the bogie trucks are usually six- or four-coupled, with no idle wheels, except, of course, in the first instance.

All “Fairlies” are tank engines. The single-boilered examples, with drive supplied only to one bogie, do not come strictly within the definition of an articulated engine, as the driven axles are rigid with respect to one another. Not a great many single-boilered “Fairlies” have been built. The second “Fairlie” type carries two boilers, placed back to back, with a separate firebox for each. Fire-holes are arranged at either end of the double cab, the coal being fed from bunkers carried alongside the boilers. The third “Fairlie” type, with double boiler, is very similar, except that the two boilers feed from a common firebox running lengthwise across the low-slung cab. The fireman works on one side of the firebox, while the driver works on the other side.

In these double-end “Fairlies” the central firebox, or fireboxes, can be made of great depth and width, as there are no restricting wheels underneath. This suggests the “Garratt”, as do the cylinders of the “Fairlie”. They are located at the outer extremities of the trucks, usually for simple expansion. The double-end “Fairlie” provides a powerful unit on mountainous railways where curves are so sharp as to hamper the working of the more lengthy “Garratt” type. Express passenger “Fairlies” are rarely designed, although high speeds are claimed to have been attained with such engines in Mexico.

“Fairlies” are chiefly used on narrow-gauge systems, although a few standard gauge examples have been used in Britain in the past. The four British main-line railways use none at present, but two are at work on the Festiniog Railway in North Wales. The curves here are as sharp as the sweep of Oxford Circus, London. The well-known little engines are the single-boilered “Taliesin”, formerly “Livingstone Thompson”, and the double-boilered “Merddin Emrys”, both of which were rebuilt recently. A third “Fairlie” engine, the “James Spooner”, is lying derelict, after forty-two years of service.

“JAMES SPOONER” a typical double-boiler “Fairlie” type engine of the 0-4-0+0-4-0 type, belonging to the Festiniog Railway, North Wales. The curves on this 1 ft 11½ in gauge line are extremely sharp. The engine-driver stands on one side of the single, long firebox, while the fireman stands on the other side. There is a rigid wheelbase of 4 ft 6 in, and a total wheelbase of 18 ft 8 in. The weight in working order is 20 tons 1 cwt. “Fairlies” are chiefly used on narrow-gauge systems.

What is known as the “Modified Fairlie” type engine, was introduced by the North British Locomotive Co, Glasgow, to the South African Railways in 1924. This type is primarily derived from the single-boilered “Fairlie”, but it might also be described as an advanced edition of the later-built “Union-Garratt”. As with standard “Fairlies”, the main frame of the “Modified Fairlie” is rigid from end to end, and not merely for two-thirds of its length as in the “Union-Garratt”. The relative positions of boiler, tanks, and bunker, however, are as in the “Garratt”, with two driven bogie trucks at either end. The South African “Modified Fairlies” are of the four-cylinder 2-6-2 + 2-6-2 type, 3 ft 6 in gauge, and scale 113 tons in running trim.

“Kitson-Meyer” Locomotives

Yet another famous type of articulated locomotive, used for the same kind of work as the “Fairlie”, is the “Kitson-Meyer” type. A Frenchman, Jean-Jacques Meyer, and his son, Adolphe, took out a patent for a completely articulated tank engine in 1861. The original “Meyer” design was not an outstanding success. As so often happens, however, an improvement on the original patent became world-famous. The modified design, itself split up into several varieties, goes by the name of “Kitson-Meyer”. It is not used in Great Britain, but is largely turned out by the British firm of Kitson & Co, Ltd, of Leeds.

“Kitson-Meyer” engines are principally of the tank type, though pseudo-tenders or even tenders are sometimes fitted. As with the “du Bousquet”, the boiler and other superstructure is carried on a rigid frame, supported by two driven bogies. The “Kitson-Meyer” firebox, however, is superior to that of the “du Bousquet”, since a space between the wheel-trucks allows unrestricted width and depth, as in the “Fairlie” and the “Garratt”. The low-pitched firebox and boiler also allow a low loading gauge to be passed. The cylinders are placed at the rear of either truck, or else at the ends of the locomotive, as in the “Garratt”. The rear cylinders are exhausted through a rear chimney, as in the triplex “Mallet”. The most common wheel formula for the “Kitson-Meyer” is 0-6-0 + 0-6-0, but engines with uneven arrangements, such as 2-6-0 + 0-6-4, have been used.

AN ARTICULATED TANK LOCOMOTIVE, one of three 2-8-0 + 0-8-0 “Kitson-Meyer” type engines belonging to the Great Southern Railway of Spain. Driving wheels are 4 ft in diameter, cylinders (4) 14¾-in by 24-in, and working pressure 180 lb per sq in. The weight in working order is 101 tons, and the tractive effort at 75 per cent of boiler pressure is 29,322 lb. The gauge is 5 ft 6-in.

The “Kitson-Meyer” is in operation in many countries, particularly in South America, where the lines crossing the Andes provide opportunities for the locomotive to show its advantages. The 3 ft gauge Girardot Railway, in Colombia, has always made a speciality of the “Kitson-Meyer” type for its mountain line, which forms the principal link between Bogota, the capital, and the Pacific coast. The most modern engines on this line, of the 2-6-0 + 0-6-2 type, have, for tank engines on so small a gauge, the exceptional tractive effort of 40,000 lb at 85 per cent boiler pressure. Driving wheels are 3 ft 1½-in in diameter, the total wheelbase is 44 ft 3 in, and the loaded weight 94½ tons. To relieve wear and tear on the brakes while descending the 1 in 25 grades, a special arrangement enables the driver to exert a steam back-pressure of 145 lb per sq in. in the cylinders.

In 1928 Messrs. Kitson & Co. supplied two remarkable “Double Prairie” or 2-6-2 + 2-6-2 type “Kitson-Meyer” engines to the North Western Railway of India. Although built for the 2 ft 6 in gauge, the engines weigh 68½ tons. They can pull 130 tons at 10 mph up 1 in 25 grades, where the curvature is of only 120 ft radius.

By way of contrast, the Great Southern Railway of Spain employs 2-8-0 + 0-8-0 “Kitson-Meyers” for the broad gauge of 5 ft 6 in. They were designed to secure large hauling power with a comparatively small axle load, to deal with heavy mineral traffic on a light permanent way. They can take 854 tons over 1 in 100 grades at 10 mph on straight track.

High speed is never attempted on the type of heavily graded, winding lines suitable for the “Kitson-Meyer”, though passenger trains are regularly hauled by the type. The “Kitson-Meyer” is at its best where a very compact machine is required. Where curves will permit of a longer wheelbase, the “Beyer-Garratt”, with its greater power and larger fuel supplies, is usually considered the more satisfactory engine.

Not all articulated locomotives are driven through connecting and coupling rods. Horizontal shafts and gears are successfully used in many instances. Of the large number of different types of geared locomotives which have been invented, the American “Shay” type, first built for a logging railway in the ‘seventies, is the best known. In the “Shay” geared engine the boiler and superstructure are carried on a single rigid frame, which rests on two, three, or four driven bogies. Every wheel is driven, including the wheels of the tender, if there is one. This means that every ounce of weight is available tor adhesion.

The “Shay” locomotive is equipped with a vertical three-cylinder steam unit on the right-hand side of the boiler. This transmits its power to a horizontal revolving shaft, which in turn is connected by gearing with each axle of every bogie. By a system of sliding sockets and universal joints, the driving mechanism is flexible in every direction, but rigid in revolution.

The absence of heavy coupling rods and counter-weights enables geared locomotives to exert even stresses upon the permanent way, and this makes them ideal for running over the light-rail track so often found in mountainous regions. The “Shay” type can mount hills of exceptional severity at speeds up to 7 mph, and can maintain 15 to 20 mph on favourable down grades. Countries using “Shay” geared locomotives include Australia, Formosa, China, Chile, Ecuador, Bolivia, Guatemala, Mexico, Santo Domingo, Canada, as well as the United States.

“SHAY” GEARED LOCOMOTIVE, Canadian Pacific Railway. This 4-4-4 type articulated engine has one pivoted truck under the fore part of the boiler and two others under the cab and tender. In front of the cab, on the right-hand side, is a three-cylinder vertical engine, which turns a flexible shaft geared to all the wheels. Locomotives of this type can ascend gradients of exceptional severity at low speeds.

“SHAY” GEARED LOCOMOTIVE, Canadian Pacific Railway. This 4-4-4 type articulated engine has one pivoted truck under the fore part of the boiler and two others under the cab and tender. In front of the cab, on the right-hand side, is a three-cylinder vertical engine, which turns a flexible shaft geared to all the wheels. Locomotives of this type can ascend gradients of exceptional severity at low speeds.

Temporary Articulation

The geared locomotive has its draw-gear and buffing - twin “buffers”, as known in Britain, are often dispensed with abroad - attached to the rigid main frame, and not to the mobile truck, as with most other articulated locomotives.

Hundreds of different kinds of articulated steam locomotives have been invented, but the types here described have exerted a wider influence than all the rest put together. Many of the lesser types have never gone beyond the experimental stage. Some success has been gained with rare articulated locomotives in which the transmission of the drive has been effected by ball and sockets, or even by chains. There has also appeared a type of semi-articulated engine equipped with an ingenious design of axle, whereby certain of the driving wheels are flexible, while others, although coupled to them, are rigid. Twin locomotives, consisting of small tank engines arranged for coupling back to back, occasionally with a double-end tender in between, have also been employed with success, sometimes on British mining railways.

A more recent development is that sometimes described as the “temporarily articulated” engine. It is the same as an ordinary rigid engine, except that one or more trailing axles, under the cab or tender, are equipped with two-cylinder steam drive which can be temporarily brought into action when required. The auxiliary two-cylinder engine is known as “booster” and was first used in America in 1919, the reversible booster following in 1928. The first temporarily articulated locomotives, of a much earlier date, had drive on the leading wheels.

A few LNER engines of the 0-8-4, 2-8-2, and 4-4-2 types comprise the only booster-fitted locomotives found in Great Britain. The most interesting of the LNER experiments is that made by Mr. H. N. Gresley, early in 1932. He took in hand two three-cylinder “Atlantic” (4-4-2) type express engines of the late North Eastern Railway, Nos. 727 and 2171, and rebuilt them in an original fashion. A four-wheeled bogie replaces the single trailing axle, and projects partly under the tender. The engine and tender are both attached to the flexible bogie, and a powerful booster is applied to the bogie’s front axle. The rear end of the tender is carried on another four-wheeled bogie, this being idle. The booster is brought into play by the engine driver when starting with heavy loads, and when climbing steep hills. In tests made, No. 727, without booster assistance, was able to start 496 tons from rest on the level; but with the booster in operation, a load of 746 tons was successfully started.

A unique temporarily articulated locomotive, with booster-driven tender, was introduced in 1933 by the Delaware and Hudson Railroad, which has been experimenting with high-pressure goods engines since 1924. The new engine is of the 4-8-0 type, with one high-pressure cylinder under the right-hand side of the cab, one intermediate-pressure cylinder under the other side, and two low-pressure cylinders in the usual positions beneath the smoke-box. All four connecting rods drive on to the second coupled axle. With the exception of certain experiments made in the ‘nineties by Mr. F. W. Webb, of London and North Western fame, this is the first time, so far as is known, that the triple-expansion system has been applied to a railway locomotive.

The Delaware and Hudson engine is named “L. F. Loree”, after the President of the Company. The tender is carried on one four-wheeled and one six-wheeled bogie, the latter being at the rear. The six-wheeled bogie has coupled axles, and is driven by an auxiliary booster engine, taking steam through flexible piping at 500 lb per sq in from the engine boiler. The booster is exhausted through a rear chimney, which is a departure from standard booster practice. The “L. F. Loree” has twice the thermal efficiency of an ordinary engine, and has an available tractive effort at starting of 108,000 lb. An illustration of the engine appears on pages 596-7 of this work. As with every branch of scientific endeavour, the engineers concerned with the design of articulated locomotives have to look to the future. Several engineering firms have designs now ready for remarkable types of articulated locomotives.

LOCOMOTIVE OF THE FUTURE. A drawing of a huge freight engine of the 2-6-6-2 + 2-6-6-2 type, for which a patent has been taken out by Messrs Beyer, Peacock & Co Ltd, of Manchester. The engine is of the “Mallett-Garratt” or “Super-Garratt” class, and has been designed to haul the heaviest goods traffic.

LOCOMOTIVE OF THE FUTURE. A drawing of a huge freight engine of the 2-6-6-2 + 2-6-6-2 type, for which a patent has been taken out by Messrs Beyer, Peacock & Co Ltd, of Manchester. The engine is of the “Mallett-Garratt” or “Super-Garratt” class, and has been designed to haul the heaviest goods traffic.

Messrs. Beyer, Peacock & Co, Ltd, for instance, have patented designs for a giant locomotive for which they anticipate the constant increase in the weight of freight trains will ultimately create a demand. It is a logical development of the “Beyer-Garratt”, and is called the “Super-Garratt”, or “Mallet-Garratt”. It differs from the “Beyer-Garratt” in that there are four, instead of two, sets of independently articulated bogie driving trucks. They are grouped in pairs, and are propelled by eight cylinders for simple-expansion. The design shown is for a 2-6-6-2 + 2-6-6-2 type.

The Strangest Locomotive

More formidable wheel formulae than this are met with in the new “Franco” type of articulated freight locomotive, which has recently been patented by Belgian engineers. One “Franco” engine has already been built, and it differs from any other loco-motive yet introduced. It consists of three sections, the outer sections having one set each of coupled wheels, and the centre section two sets. The wheel formula is 0-6-2 + 2-4-2-4-2 + 2-6-0.

The centre section houses two boilers and two fireboxes, arranged back to back and obliquely to one another, so that the specially shaped fireboxes stand side by side; they thus resemble a single firebox divided by a diagonal cross partition. They are fired from opposite ends by two firemen working simultaneously. The driver occupies a compartment at either end of the central portion, according to the direction of travel.

The two outer portions contain the water supplies, the superstructure being in each instance integral with the six-coupled bissel truck. The superstructure of either portion comprises a large tubular feed-water-heater, with a smoke-box and the usual chimney and blast pipe at the end.

The pioneer 0-6-2 + 2-4-2-4-2 + 2-6-0 type “Franco”, which was completed in 1932, has eight cylinders for simple expansion. The boiler pressure is 200 lb per sq in., the tractive effort 83,130 lb, and the service weight 243 tons. The designers claim that the “Franco” system reduces fuel consumption and maintenance costs, and makes for a higher thermal efficiency than is possible with a normal locomotive.

THE WORLD’S STRANGEST STEAM LOCOMOTIVE, the first of the new “Franco” articulated type, on test in Belgium. The main central unit houses two boilers and fireboxes and the compartments occupied by the driver and his two firemen. The engine has the unusual wheel formula of 0-6-2 + 2-4-2-4-2 + 2-6-0.

THE WORLD’S STRANGEST STEAM LOCOMOTIVE, the first of the new “Franco” articulated type, on test in Belgium. The main central unit houses two boilers and fireboxes and the compartments occupied by the driver and his two firemen. The engine has the unusual wheel formula of 0-6-2 + 2-4-2-4-2 + 2-6-0.

You can read more on

“A New and Novel Articulated Locomotive”,

“Giant American Locomotives”,

“Locomotive Giants of other Countries” and

“Unconventional Locomotives”

on this website.

A FORMER “ATLANTIC” TYPE express engine of the North Eastern Railway, as rebuilt by the LNER, with booster-

A FORMER “ATLANTIC” TYPE express engine of the North Eastern Railway, as rebuilt by the LNER, with booster-

A MODERN EXAMPLE of the “Mallet” type of semi-

A MODERN EXAMPLE of the “Mallet” type of semi-

A POWERFUL TANK ENGINE of the 0-

A POWERFUL TANK ENGINE of the 0-

“SHAY” GEARED LOCOMOTIVE, Canadian Pacific Railway. This 4-

“SHAY” GEARED LOCOMOTIVE, Canadian Pacific Railway. This 4- LOCOMOTIVE OF THE FUTURE. A drawing of a huge freight engine of the 2-

LOCOMOTIVE OF THE FUTURE. A drawing of a huge freight engine of the 2- THE WORLD’S STRANGEST STEAM LOCOMOTIVE, the first of the new “Franco” articulated type, on test in Belgium. The main central unit houses two boilers and fireboxes and the compartments occupied by the driver and his two firemen. The engine has the unusual wheel formula of 0-

THE WORLD’S STRANGEST STEAM LOCOMOTIVE, the first of the new “Franco” articulated type, on test in Belgium. The main central unit houses two boilers and fireboxes and the compartments occupied by the driver and his two firemen. The engine has the unusual wheel formula of 0-