© Railway Wonders of the World 2012-

The Poultney Locomotive: A New Type of Modern Design

Increased Power with a Minimum Coal and Water Consumption

The Poultney Locomotive

THE modern methods of operating railways, coupled with increased working costs and altered labour conditions, have naturally created a demand for more powerful locomotives and greater economy in working. In an endeavour to meet these requirements a new type of locomotive has been designed by Mr. E. C. Poultney, OBE, associated with Mr. A. H. Calling and Mr. H. A. Akroyd of the Yorkshire Engine Co. Ltd, Sheffield.

The new type, which incorporates the articulated principle already familiar to readers, is specially designed for moderate speed, heavy freight service. The basis of the new design is the increased power for a given steam production, obtained by using the limited cut-

The two chief objects attained by the new type are increased power in existing locomotives, with the same coal and water consumption, and locomotives of greatly increased power over ordinary types with reduced coal and water consumption.

The underlying principle of locomotive design is that connecting weight and power. Most locomotives consist of an engine and tender and of the combined weight of these, only part of that of the engine portion is available for the purpose of traction, the amount varying according to the wheel arrangement. For engines having the 4-

In ordinary types of locomotives any increase in power is usually only obtained by augmented adhesive weight, but this is not always permissible owing to restricted axle loads. There is no reason why the weight of the tender, or part of it, should not be used, however, for the tender offers a possible means of converting its dead weight into useful effort. In the Poultney system full advantage is taken of this opportunity by applying driving gear to the underframe of the tender. This results in two special advantages, which are that for a given axle loading on the engine the tractive effort of the locomotive can be increased; and that for a given tractive effort, axle loads, and hence bearing pressures, may be decreased.

Using part, or all, of the tender weight for driving wheel weight means that, of the total adhesive weight 60 to 70% will be on the engine portion, and 40 to 30% on the tender. A general study of many locomotive examples has brought out the fact that 70% of the total power can be developed by the engine and 30% by the tender, and of the entire locomotive weight, that available for traction may run about 70% of the total, instead of not more than from 55% to 60% for locomotives of normal construction. The advantage gained by utilising the tender weight in this manner is obviously very important.

Having thus briefly outlined the problems involved from the weight utilization standpoint, it is desirable to consider boiler capacity and engine characteristics. But first of all let us deal with the adhesive factor -

On the engine portion of the locomotive, the cylinder volume will either be 25% larger, or the steam pressure may be increased by a like amount. Alternatively, these two characteristics may be modified to produce an equal effect.

On the engine portion of the locomotive, the cylinder volume will either be 25% larger, or the steam pressure may be increased by a like amount. Alternatively, these two characteristics may be modified to produce an equal effect.

Owing to the locomotive being arranged on the limited cut-

On the tender portion, the cylinders used are of a suitable size to make use of the steam saved by the curtailed cut-

There is no difficulty in obtaining a fairly high adhesive factor when calculating on a half-

We must now say something about this 50% cut-

As most of our readers know, the amount of steam supplied to a cylinder during each stroke of the piston varies according to the extent of the movement of the cylinder valves. This movement is controlled by a shifting link embodied in the valve gear, and can be regulated by moving a lever conveniently situated in the engine cab. “Cut-

The statement that an engine works at “50% cut-

In the Poultney Locomotive the maximum cut-

In the matter of boiler power it is evident that the actual power obtainable from any boiler depends on the evaporation and on the use made of the steam generated. The evaporation per square foot of heating surface may be large, but the economic performance of the engines may be such that the power developed may be relatively low.

The idea underlying the 50% cut-

The Poultney Locomotive is thus based on principles already proved, because it is a 50% cut-

The use on the engine portion of cylinders of such size that, combined with the available steam pressure, they can furnish sufficient power to absorb a given percentage of the adhesive weight and at the same time be operated at a maximum of 50% cut-

The use on the engine portion of cylinders of such size that, combined with the available steam pressure, they can furnish sufficient power to absorb a given percentage of the adhesive weight and at the same time be operated at a maximum of 50% cut-

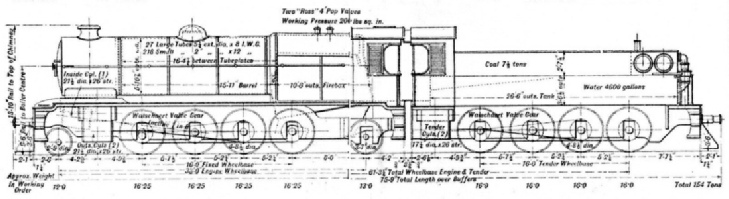

The combined heating surface of the boiler on the Poultney Locomotive is 3,718 sq ft, and as the grate is 65 sq ft, the ratio is about 57 to 1. Actually, the boiler factor (i.e., 59372 ÷ 3718) is 15.9, but when compared with a 90 per cent, cut-

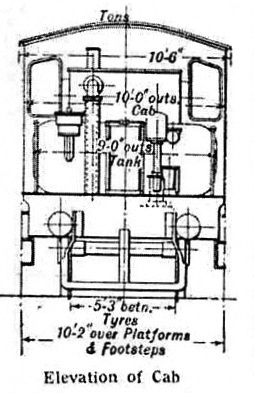

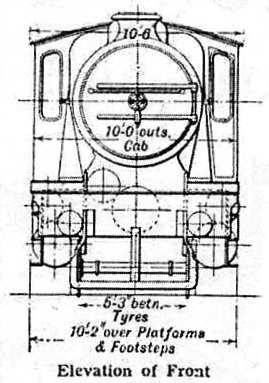

The general arrangement of this particular design is well shown, and it is certainly a very practical idea to place the heater equipment on the tender, as generally the heaters are fixed on the top of the tank so that the condensate may pass to the tank through a suitable filter. This is one of several minor but none-

Further to improve the performance of the Poultney Locomotive, the exhaust from the tender engines is employed to heat the feed-

Assuming an ordinary locomotive to cut-

From the above, the piston area of the Poultney engine is 125 + 55 = 180, and the percentage of work done on the tender is 30. The total volume to cut-

As the engine portion represents the same power as when working with the smaller cylinders at the long cut-

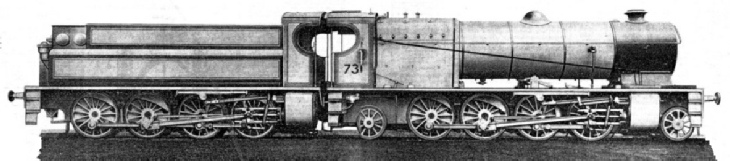

The arrangement of the Poultney Locomotive is similar in all essentials to an ordinary engine and tender, and the arrange-

The exhaust from the engine portion cylinders is utilised for the blast, and that from the tender cylinders is employed for heating the feed-

Due to the above arrangement, the engines on the boiler portion are always proportioned so that they develop not less than 67 to 70% of the total locomotive power. When the steam pressure is increased, then of the total piston area designated by the value 164, 70% should be oh the boiler portion leaving 49.2 on the tender. The cylinder volumes must therefore be 1:2.31, the larger value being of course that representing the cylinders on the engine.

From the foregoing it will be seen that the following cylinder ratios obtain. Increasing the engine portion cylinders 25% means a cylinder ratio of 125:55 or 2.27:1. Increasing the boiler working pressure 25% means a cylinder ratio of 114.8:49.2 or 2.33:1.

We come now to the manner in which the Poultney loco combines the good points of both compound and simple types.

It will be evident from what has been said of the 50% cut-

In order to effect easy starting at all crank angles, a special piston valve has been designed. The valve is of the narrow ring type having two heads in which, on the steam side, are cut starting ports communicating with the steam ports. The relation that these ports bear to the main ports is such that actually steam is not cut-

The starting ports in the valve are out of balance -

The starting ports are arranged to move over specially-

I n its characteristics the Poultney Locomotive is equal to a locomotive of the compound type but has the same freedom in running as the simple. This is made possible by the fact that the excessive back pressure present in the high-

n its characteristics the Poultney Locomotive is equal to a locomotive of the compound type but has the same freedom in running as the simple. This is made possible by the fact that the excessive back pressure present in the high-

Compared with the usual forms of articulated locomotives, the pipe connections required for locomotives built on the Poultney system are very simple. There is required only one flexible joint subject to high pressure steam and none for exhaust steam.

The tender feed-

As far as boiler feed piping is concerned, it is of a simpler character than that required for other well-

As we mentioned at the beginning of this article, the principal object of the Poultney system is an increase of up to 30% in the power of an existing locomotive without increasing either the axle load or the size of the boiler. This object is achieved by the use of additional cylinders on the tender and taking advantage of the weight of the tender for adhesion. The steam demand is no more than that of an ordinary locomotive of 30% less power and therefore no larger boiler is required. To obtain this increase in power, however, the combined areas or volumes of the cylinders in the Poultney system are about 50% larger than those of an ordinary locomotive.

Although at first sight it might be supposed that the power gained by the increase in cylinder capacity might balance the steam saved by the shortened cut-

Working these values out for different ratios of cut-

Cut-

M.E.P. .947 .919 .888 .858 .8235 .75.6666

To obtain a co-

Cut-

Co-

Cut-

Co-

It will be seen that the values for 90% and 50% are confirmed by American and Continental useage, where co-

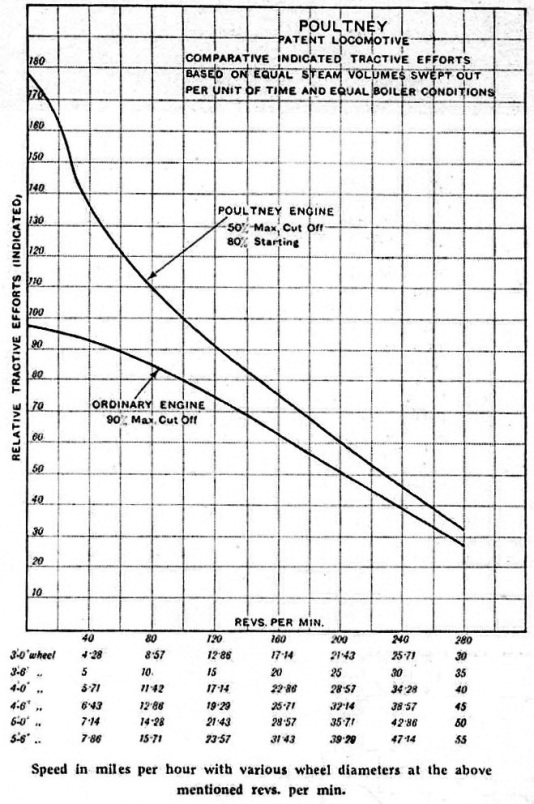

These conditions prevail at about 70 revolutions per minute, see accompanying diagrams which shows that an enormous

increase of tractive effort is claimed at starting. This presents something of a problem to the uninitiated, as if the cut-

It is interesting to find that the restriction of the maximum cut-

The blast from the engine cylinders is quite strong enough to make steam for both engine and tender, because the steam taken for the tender cylinders goes back to the boiler in the form of heat -

The objection to running ordinary locomotives tender first does not apply to the Poultney Locomotive as the tender is self-

Incidentally it may be mentioned that the water level in the tank is very little disturbed when working on even the steepest grades.

No centre pivots are employed, the connection between the engine and tender units being of a type and design well established. In this, as in all other features of the Poultney Locomotive, experiments and fanciful ideas form no part in its constructive characteristics.

The “Poultney” locomotive is the most recent successful attempt to design a locomotive for heavy traffic purposes which, while conforming to the requirements of the British loading gauge and retaining the ability to negotiate comparatively sharp curves, possesses greater power than locomotives of the conventional type. Earlier efforts to solve this problem resulted in the production of the “Fairlie” and the “Garratt” locomotives.

The most powerful “Garratt” yet built attracted a great deal of attention when it appeared in the Railway Centenary Procession at Darlington in July 1925. This monster differs from the “Poultney” loco in being a “double-

The original “Fairlie” articulated locomotive had as its outstanding features a central firebox with two barrels projecting longitudinally and two smoke boxes and chimneys,, while the tanks were located alongside the boiler. Later the design, was greatly modified and improved and the double-

The Poultney locomotive

You can read more about “Articulated Locomotives”, “Experimental Locomotives” and “Locomotive Giants -