The “Fairlie” Double-ended Locomotive

A Design of Engine Evolved to Operate on Sharp Curves and Stiff Gradients

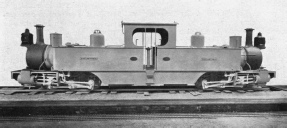

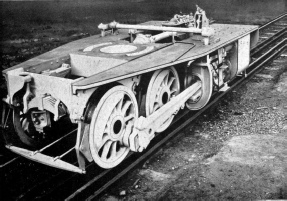

THE “FAIRLIE” LOCOMOTIVE used on the Bolivian narrow gauge railways.

FROM time to time ingenious efforts have been made to depart from what may be described as the orthodox in locomotive design. Such ingenuity has been prompted by the desire to obtain an engine which will meet peculiar prevailing conditions more efficiently than the familiar type of locomotive.

This quest is by no means of recent date. The necessity of some such development was realised in the days when railways were young. The engineers of motive power found it difficult to secure economical working upon the roads with their sharp curves and heavy banks laid by the early railway builders. The fact that the cheapest and easiest extrication from the quandary was to rebuild the lines was not recognised at that time; or, if it was, the treasuries were not sufficiently rich to sanction costly reconstruction, Accordingly the mechanical engineer was compelled to make the most of a bad bargain, and this situation stimulated his ingenuity to a marked degree.

The countries which were the greatest offenders in this respect were those of recent exploitation, or which were only beginning to attract commercial interests such as Australasia and the South American States. There the railway builders, hampered by scarcity of funds, reduced the cost of construction to the lowest possible level carrying their tracks over obstacles with long stretches of banks running up to 1 in 25, and writhing and twisting through favourable channels intersecting the mountains in an amazing manner, so that curves of 250 feet radius were more the rule than the exception. The builders scarcely gave a thought to the railway operator.

As the years rolled by, and the traffic over these lines became heavier, it grew more and more difficult to adapt the ordinary type of locomotive to the work with any pronounced degree of cheap working. In the attempt to surmount the difficulty many freakish designs were devised, but, needless to say, they only enjoyed a fleeting existence. They were ingenious, it is true, but being more novel than practical, they only helped to swell the inventor’s scrap-

Among these tireless experimenters was a Scottish engineer, Robert Francis Fairlie. He passed through the stern school of practical railway experience both in Ireland and India, finally relinquishing active operations in favour of a consulting engineer-

In 1864 he introduced his solution of the problem, and the unusual design aroused considerable interest. It resembled two tank engines placed back to back with a common cab and boiler. Each moiety appeared to be complete, with its smoke-

THE DOUBLE BOILER, FIRE-

Despite its unusual appearance, the engine substantiated the claims of its inventor, and was adopted promptly in those hilly countries where curves and grades were adverse to the ordinary locomotive. It was introduced into New South Wales, New Zealand, the South American countries, Russia, Sweden -

The system, of course, possessed disadvantages. The mechanism was somewhat more complicated; trouble was exper-

Taken all round, however, the Fairlie engine meets the peculiar situation and purposes for which it has been designed very effectively. Now it may be seen working in all parts of the world where the country threaded is mountainous and where inclines are steep and curves are sharp. Up to the present no other type of engine has proved more suited to the work and as a result large and more powerful Fairlie engines have been built meet exigencies of traffic over the lines upon which they were introduced. In fact, in certain instances, so far, it has been the means of avoiding the costly process of re-

A HEAVY POWERFUL “FAIRLIE” LOCOMOTIVE, BUILT FOR THE MEXICAN RAILWAY. It weighs 138 tons. The photograph shows the disposition of the driving wheels on two bogies and the driver’s position on the footplate. Comparison with the man gives an impressive idea of its large proportions.

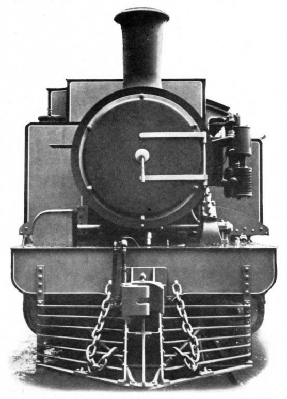

The Mexican Railway has three of these engine which are among the most powerful and largest of their character that ever have been constructed. They we built at the Newton-

The two boilers, each measuring 12 feet 11 inches in length by 5 feet outside diameter, and containing 216 steel tubes, are in one piece, though there are two separate fire-

Each bogie truck carries three pairs of driving wheels, 4 feet in diameter, the wheel base of the bogie being 9 feet 3 inches, while the total wheel base is 35 feet 6 inches. The four cylinders -

END VIEW OF THE MEXICAN RAILWAYS heavy “Fairlie” engine

The valve-

Either coal or oil fuel may be used. The regulator and driving control are placed on the footplate on one side the fire-

These engines have proved highly successful in Mexico and are performing excellent work. They are engaged in hauling trains weighing 840 tons over the stiffest banks and the sharpest curves, at a speed of 9 miles per hour.

Another engine of this type, though differing in certain conspicuous features which emanated from the Sheffield works of the Yorkshire Engine Company, Limited, is working upon the 2 feet 6 inches gauge lines of the Bolivian Railways. Here the grade runs up to 1 in 30 while the curves are as sharp as 280 ft radius. These engines not only had to capable of handling heavy loads over such difficult portions of the system, but had to be capable of completing long runs well.

In this instance, instead of there being one double boiler, there are two separate boilers of the Belpaire pattern. This arrangement not only reduces the trouble experienced in connection with the variations of the water level within the boiler owing to the inclination of the engine but provides a roomier cab similar to that of the ordinary engine. The water tank, capable of carrying 1,500 gallons of water, are continued under the platform of the cab. The motor bogies, each with three coupled wheels of 2 feet 6 inches diameter have a rigid base of only 6 feet, the total wheel base being 29 feet 4½ inches. The centre pair of wheels on each bogie is flangeless, and each bogie carries two outside cylinders, having a diameter of 12½ inches by 16 inches stroke.

Owing to the narrowness of the gauge the centre of gravity is kept very low, the centre line of the boiler being only 4 feet 10½ inches above rail level. The boiler measures 9 feet 3¾ inches in length by 3 feet 5⅛ inches diameter, and contains 106 tubes, the total heating surface being 1,046.88 square feet, and the grate area 21.66 square feet.

In this engine the reversing shaft is carried along the tops of the tanks, the gears being coupled and operated with a screw and wheel action carried on a pillar in the centre of the footplate. The steam distribution also is carried out upon improved lines, with the object of overcoming the difficulty in keeping the pipes and joints steam-

Although many efforts have been made to devise an engine superior to the Fairlie for the service in which this locomotive excels the broad principles laid down by the Scottish engineer half-

ONE MOTOR BOGIE OF THE “FAIRLIE” ENGINE used on the Mexican Railway.

You can read more on

“A New and Novel Articulated Locomotive”

on this website.