© Railway Wonders of the World 2012-

Rolling Stock Construction

Special methods Adopted to Meet Modern Demands

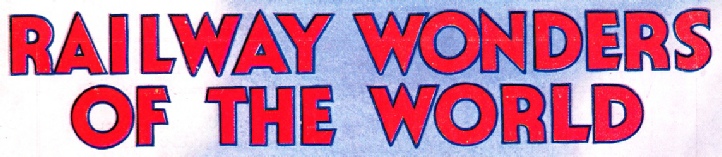

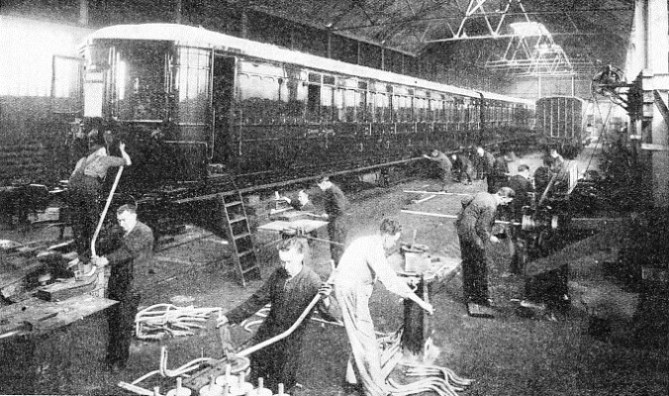

EXTERIOR DECORATION is an important part of railway coach building; here are men at work “lining” a carriage at the LNER shops at York. In 1934 there were some 43,450 passenger carriages on the four chief British systems, with a total seating capacity of 2,506,000.

We have seen in the chapter beginning on page 751 how a modern steam locomotive grows from a heap of grey iron castings, rough steel plates, and forgings to a veritable giant of power and speed. But neither passengers nor goods can be carried on an engine, and railway travellers would undoubtedly find the footplate more interesting than comfortable. The design and construction of coaches and wagons is, therefore, an important feature of railway work.

The building of rolling stock presents all kinds of difficulties, and numerous problems have to be solved. Technical details of design are settled by the engineers, but other items call for the attention of many widely differing trades. To the work of the engineer on under-

The undercarriage framework generally consists of two channel girders of [ section, or of sole-

Bogie frames also are welded in many of the shops, and the wheels are turned and fitted to the axles in a similar way to those of the locomotives. The completed under-

An important item is the train lighting equipment. All modern rolling-

Undercarriages are usually built in one of the engineers’ shops, and are then drawn into the carriage erecting shop for final assembly of the woodwork and additions of the fittings and equipment.

There are in Great Britain a number of famous firms that specialize in the building of coaching stock, not only for British railways, but also for service all over the world. The four large railway companies, however, usually make their own coaches and wagons, and construction is carried out on the most modern systems of mass production.

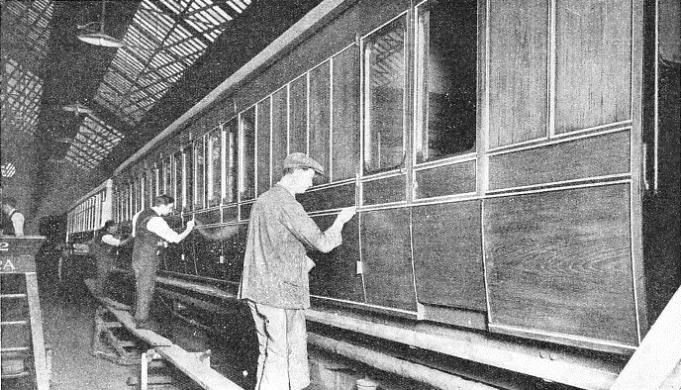

FINELY UPHOLSTERED SEATS for new electric coaches on the Southern Railway.

This photograph shows a scene of activity at the Southern’s carriage shops at Lancing, Sussex.

Formerly the building of a railway carriage took about six weeks, with a small army of carpenters and joiners making the component parts and fitting them in place. Improved organization and methods of production have reduced the above time to a period of only six hours for the construction of the coach body, including the roof. Such efficiency has been rendered possible by the use of jigs for the accurate making of every part. Some of the most up-

If we consider a typical carriage works, the first place of interest will be the timber yard, where tree trunks and baulks of timber are stored for use as required. First the logs are cut into planks of varying thicknesses. Drying sheds are used to condition the timber and ensure that it is properly seasoned.

Carriage components are first cut to size by a circular or a band saw, and are then fed forward over a series of rollers to planing machines provided with high-

In these works the machining operations are so arranged that the timber flows in a continuous stream from one machine to another, and the rough wood is delivered as a finished component ready to assemble in the erecting shop. The whole process is facilitated by the provision of roller “run-

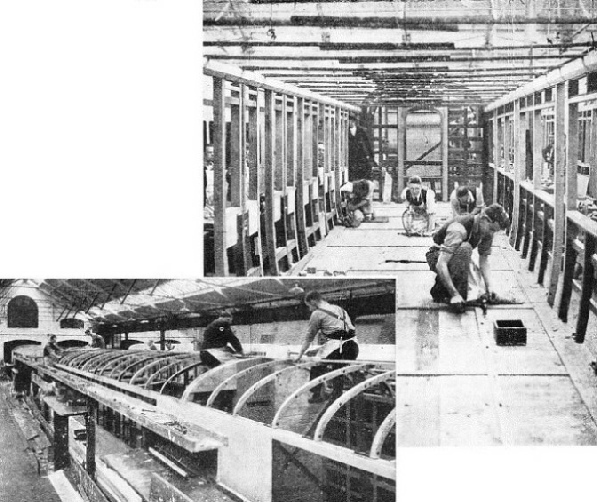

The next process is the assembling of the component parts of the coach. At the Swindon carriage works of the Great Western Railway the procedure is first to construct the floor which will rest on the under-

Inside compartments and corridor partitions are added next, and then the doors. Next, steel-

After seat frames have been fitted in the compartments, the body is placed on its undercarriage and run into the paint shop. Here it receives attention at the hands of the finishers, trimmers, and painters. The steel panelling on the outside of the coach is cleaned and prepared by workmen, who are followed by others who paint the metal surface. The lining of the paintwork and the affixing of crests and numerals is then undertaken; finally the whole of the exterior is given two coats of varnish. The undercarriage is painted with red lead before it enters the carriage body shop, and, after the addition of the coach-

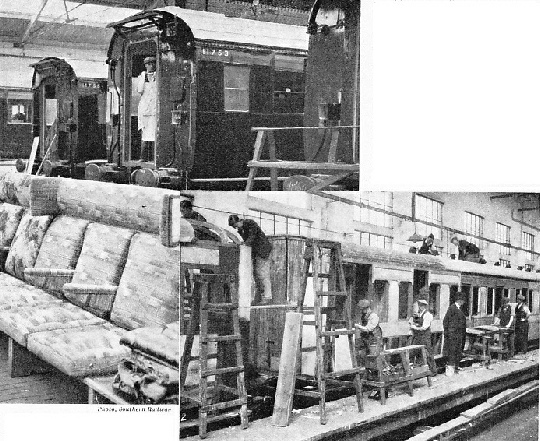

THE FRAMEWORK of a passenger coach under construction at the Great Western Railway shops, Swindon. Oak is extensively used for the wooden sections.

A VIEW of men in the process of fitting a carriage roof at the Southern Railway’s works.

The upholstering of carriage seats is carried out in the trimming shop, where the linings and covers are cut out by a machine in layers about 4 in deep. Sewing machines are then employed in the making-

Other departments set aside for the preparation of carriage components are the French polishing and the finishing shops. In the former, women are employed in staining, filling, and polishing the interior doors and decorative woodwork of the coaches. The finishing shop is allocated to the preparation of the interior woodwork of the carriages such as corridor, lavatory, and gangway doors, frames for seat backs, panelling, luggage racks, and woodwork for electric lighting.

The wood refuse and sawdust in the sawmills and other shops is sucked up by large pipes and conducted to a furnace used to raise steam for shop heating and wood bending.

Many remarkable machines are used in the production of a modern railway carriage. It is not generally realized that the machines used in shaping the timber turn out work that is accurate to a limit of a two-

The advantage of such accuracy is clearly demonstrated by the method adopted in the LMS shops when fitting a roof to the body of a carriage. The completed roof is suspended over the coach and, after being lowered into position, is pulled down on the ends and sides of the vehicle by means of compressed air cylinders. Some ninety tenons thus slide into their appropriate mortices in one rapid movement.

In the making of doors an ingenious machine holds the pillars and cross members, previously mortised and tenoned, in position by four hydraulic rams. The screws are then inserted and the door frame is complete and ready for attachment to the coach.

Screw-

With the use of steel for coach building a new technique has been rendered necessary in construction. To take advantage of the strength and safety afforded by steel framework, and at the same time to reduce weight, welding is resorted to instead of the customary riveting. Welding is done by electricity or the oxy-

In a modern steel coach the bogies are welded throughout, with the exception of the brake-

The floor of a modern steel coach, particularly of a sleeping car, is carefully insulated to eliminate noise and vibration. The steel sheeting on the under-

The underside of the floor is sprayed with asbestos compound to a depth of ⅜-

It is not generally appreciated that a main-

Goods wagons are also built by mass-

Roller Bearings

Continuous acting brakes are not usually fitted to the smaller types of wagon, but hand brakes are used that can be set to any required pressure to retard a goods train on the descent of a long and steep gradient.

After delivery to the erecting shops the wagon under-

High-

The forty-

Quite frequently goods wagons are built for special purposes, and their construction involves careful design so that they may be suitable for their intended purpose, and at the same time not place too great a strain on the permanent way over which they will have to travel.

The cost of construction of wagons used on British railways gives an excellent indication of the enormous sums expended by all railway companies on their rolling stock. For example, a twenty-

AT LANCING, in the Southern Railway’s shops, where rolling stock for the world’s largest electrified suburban system is manufactured. With the steady increase of the frequent electric services, carriages and motor vehicles have constantly to be supplemented.

You can read more on “International Sleeping Cars”, “Modern Passenger Rolling Stock” and “The Railway Carriage” on this website.