Dividing Express Trains at Speed

ROLLING STOCK - 5

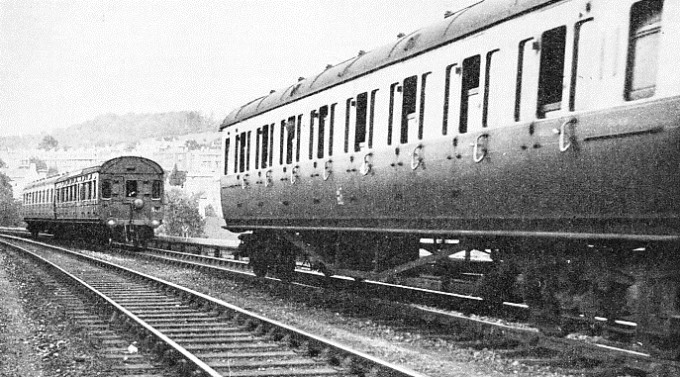

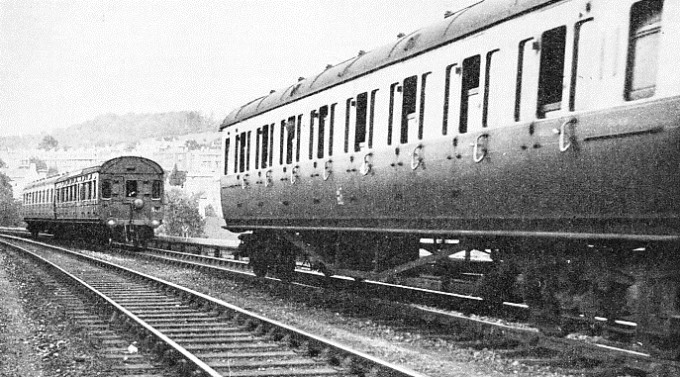

AFTER THE SLIP. A Great Western Railway Bristol express just after it has detached the slip portion. The two detached coaches are running of their own accord into Bath Station. The London-Bristol expresses now stop at Bath, but the railway still has many slip-coach services.

SLIP-COACHES were invented comparatively early in the history of British railways. Early in 1858 the then London, Brighton and South Coast Railway made the first experiments on record with slip-coaches, dropping a Lewes portion from the rear of a Brighton express at Hayward’s Heath. By December, 1858, the Great Western Railway had also begun, and the first GWR slips were detached at Slough and Banbury. In 1869, on the Bristol and Exeter Railway - now part of the Great Western - the “Flying Dutchman” began the practice of slipping a coach at Bridgwater. Since then the Great Western Railway has always been partial to the device. Before the war of 1914-18 some of the other important British railways had more or less numerous slip-coach services; but in recent years they have almost all disappeared except on the Great Western, and one or two on the Great Central and Great Eastern sections of the LNER. Even on the Great Western their popularity is less than it was.

One objection to slip-coaches is that an extra guard is required to work the slip-coupling. Further, it has never been found practicable to “slip on” a coach to a moving train, and, for the return journey, the slip-carriage has to be attached to a train in the ordinary way. A third objection - that the slip-coach passengers are cut off from the restaurant car - was met by the former London and North Western and Midland Railways with corridor slip-carriages. Such a vehicle was daily attached to the pre-war Fleetwood Boat Express from Euston and slipped at Nuneaton, whence, attached to another train, it proceeded by a devious route to Buxton. Similar coaches were slipped at Coventry from the Birmingham “Two-Hour Expresses”.

Nervous passengers sometimes were tearful that their carriage might be slipped at the moment when they were stepping through the vestibule gangway to or from the restaurant car; but due precautions were taken to avert such an eventuality.

Railwaymen of past generations always ascribed the original idea of the slip-coach to an incident which occurred in the days before continuous brakes came into general use. The story goes that a high railway official, wishing to travel to a certain important junction, went to the terminus to catch his train. It so happened that there was a train at either side of the platform; the train on the left was a non-stop express, and that on the right a fast train which called at several of the principal stations, including the one at which the official wanted to alight. He did what thousands of other railway travellers have done, and probably always will do - boarded the wrong train, and did not find out his error until the express passed through several stations at which the other train was booked to stop. He had just resigned himself to a weary journey back on a “local”, when, to his astonishment, his carriage began to slow down and finally stopped at the platform of the junction which was his intended destination. His surprise was nothing to the shock he received when he alighted and found that the rest of the train had disappeared altogether, excepting the solitary carriage in which he had travelled.

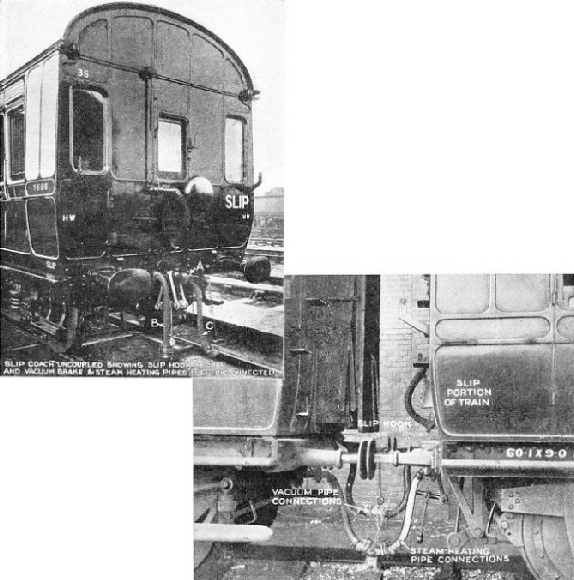

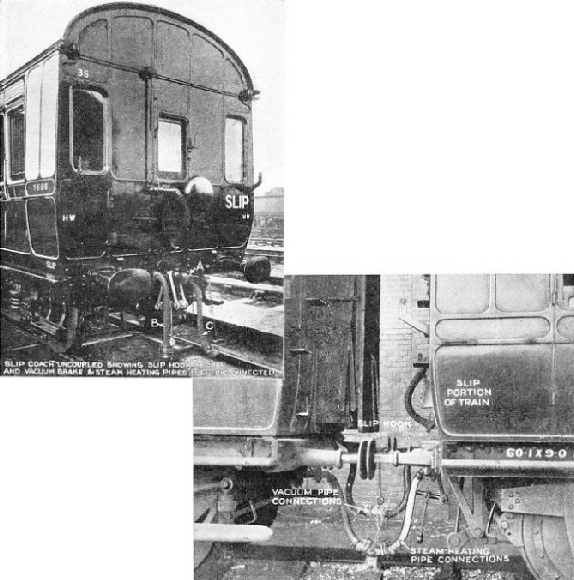

FRONT VIEW of slip coach, showing the slip hook open, the brake and steam-heating pipes disconnected, and the warning bell used by the slip guard.

JOINED TO THE TRAIN. The slip coach has the slip hook closed, and the couplings and brake and steam-heating pipes connected.

Formerly the couplings between the carriages were of the simple hook-and-chain type; some had additional “safety” chains and others did not. What had happened was that the official was riding in the last coach, which contained the guard’s compartment and was fitted with a hand brake. Two miles or so before the junction, at the top of a long grade, the coupling chain had broken. Jerks were so frequent in those days that the guard had taken no notice of the occurrence until his van began to slow down. On looking out of the window, he saw to his consternation that he was left behind, and that the train was disappearing around a curve ahead. The driver had no idea that he had lost a carriage, as there were no continuous brakes, and the “string” communication cord attached to a primitive single-stroke bell on the side of the tender could be easily snapped without giving a warning. The guard thought the best thing to do was to let the forlorn carriage coast into the junction, if it had sufficient “way” on it, and then pull up at the platform with his hand brake, which he did. Thus the mishap hurt nobody, and proved fortunate for the official.

Here, however, was a valuable idea. It a carriage could be left behind by accident, and convey passengers safely to a station at which the train did not stop, why could it not be done deliberately and thus save delay? In a short time the slip-hook coupling was evolved, and the slip-coach, as we know it to-day became a regular feature of railway operation.

The slip portion of a train is not limited to one coach only; so long as the coach with the slipping apparatus is placed next the “fixed” part of the train, the slip portion may be made up to any required length within certain limits. Neither is a train limited to one slip portion only; it necessary, a train could leave London for Glasgow or Edinburgh, for example, with fifteen coaches, and make a non-stop run, arriving with only two coaches, the rest being left behind at the principal stations on the way. The “Cornish Riviera Express” of the Great Western Railway, in its winter formation, has two slip portions, detached respectively at Westbury and Taunton. At one time in its career it had three slip portions, the third being detached at Exeter.

There is no fundamental difference in construction between slip coaches and ordinary coaches. Any coach, so long as it has a guard’s compartment, may be fitted up for slipping by the replacement of the ordinary couplings by those of the detachable type; and ordinary coaches may be coupled in behind it without any alteration being necessary.

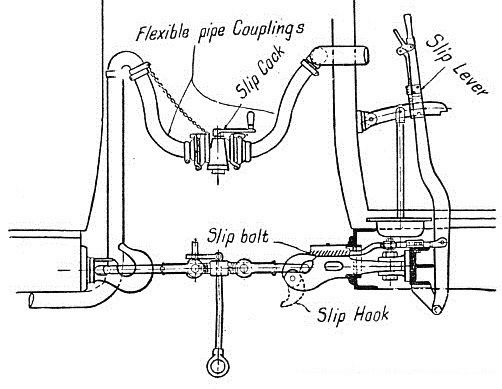

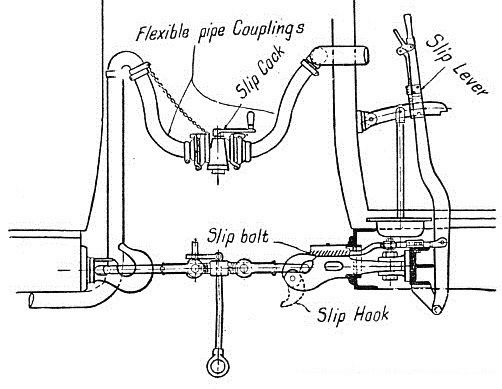

Slip couplings are of two types; in one, the draw-hook is hinged, and in the other, the shackle is jointed instead. In the former, the part of the drawbar which passes through a steel plate fixed to the headstock or end sill of the carriage frame is the same as on an ordinary coupling; but the hook itself is hinged at the bottom, which allows the “nose” of the hook to swing out forward and fall down, thus freeing the coupling shackle. When the hook is closed a sliding bar projects from the headstock just above the coupling, bears on the end of the hook, and prevents it from lifting and falling forward. The other end of the sliding bar is connected to a lever in the guard’s van.

The hinged shackle works on a fixed hook. It is very simple in action, and operates in precisely the same manner as a common snap padlock, with a catch held in the closed position by a spring. A stout cord or chain is attached to the catch; and on this being pulled by the guard, the shackle flies open (just as the padlock shackle does when the key is inserted and turned) and falls off the drawhook.

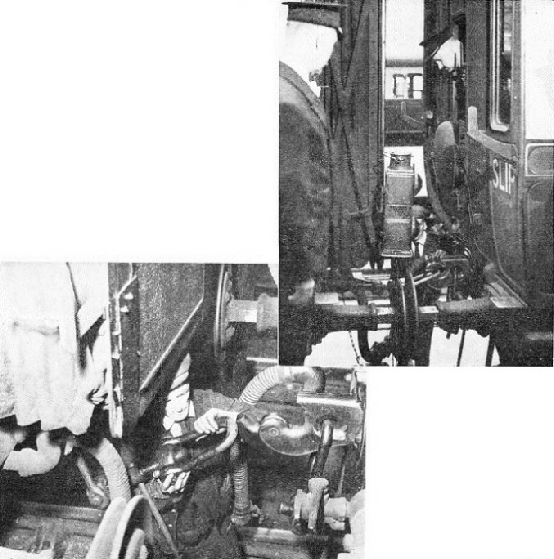

AT THE STARTING POINT. The slip coach is seen being coupled to the main train at Paddington Station. This is the rear slip on the “Cornish Riviera Express”; and the distinctive double tail-lamp of the second slip is seen on the left.

THE SLIP HOOK (open) is about to receive the screw-coupling shackle of the main train, after which it will be closed. Its release by the slip guard will cause the disconnexion of the coach.

Readers have already seen, in the chapters on the brakes, that the brake hoses will uncouple of their own accord if they are pulled into a straight line, remaining coupled only while they hang down in a curve; so there is no difficulty in disconnecting brake pipes. As, however, the brakes would go on automatically in both parts of the train if the pipes were left open, provision has to be made for closing them. On some coaches fitted with air brakes, a small trap-door is provided just above the angle cock on the train pipe at the end of the coach. The slip guard shuts the cock on the slip through this trapdoor. The cock at the rear of the main train is then closed automatically just before the slip is made; and, where the trains are steam-heated, the cocks on the steam pipes can be shut off as well. Sometimes no trap is provided, but the cocks are arranged inside the brake compartment instead, close to the lever which operates the hook.

On some of the railways using vacuum brakes, cocks are provided on the ends of the hoses themselves, just behind the couplings. These cocks are made of gunmetal and fitted with a double-armed handle. The handle on the slip-coach part is longer than that on the train pipe coupling, and has a cord or chain connected to it so that it can be operated by the guard. The handle on the train pipe coupling is shorter, and has no connecting cord or chain; but, when the hoses are coupled up, it lies parallel with the handle of the cock on the slip-coach coupling, and almost touches it. When the guard pulls the chain, the handle of one cock operates the other, and both are shut off. No cocks are used on the Great Western slip coaches; when a carriage is slipped and the hoses come apart, a spring-operated automatic valve comes into action and seals the apertures, preventing air from getting in and applying the brakes.

When one coach only is slipped, the guard can stop it by applying the hand brake with which all brake vans are provided - hence the name; but where the slip portion consists of two or more coaches, the continuous brake must be used. It is obvious that some means of releasing the brakes, as well as applying them, must be provided; otherwise if the coaches “stopped short” it would mean sending an engine to haul them to the platform. This is done by providing the slip coach with an auxiliary air reservoir, similar to that on the locomotive, or a vacuum chamber exhausted to a high degree of vacuum. A guard’s brake valve, similar to a driver’s brake valve, but generally of much simpler construction, is fitted against the end window of the guard’s compartment. When using the air brake he applies it by letting out some of the air from the train pipe; but, if he wishes to release it, he moves the handle to “release” position, which allows air to flow from the auxiliary reservoir (charged by the air pump on the engine while the slip-coach was running with the train) into the train pipe. This releases the brakes.

With the vacuum brake, the guard admits air to the train pipe for a brake application; to release brakes, he puts his handle to “release”, which immediately connects the train pipe with the highly exhausted vacuum cylinder. This extracts the air from the train pipe, and the brakes become released. As the slip-coach has neither air pump nor vacuum brake ejector, this could not go on indefinitely, but three or four applications can be made. This, however, is rarely necessary, as the slip guards are usually as “handy” with their brake valves as the engine driver.

MECHANISM OF THE SLIP. The diagram shows the way in which the slip lever pulls back the bolt that keeps the slip hook closed, and the method of uniting the vacuum brake couplings.

Great care is always taken in the manufacture and maintenance of the slip apparatus. It must not only be unfailing in its action, but it also has to operate on what one might term “split-second schedule”. A small hesitation, or premature operation, may give the passengers the nasty jolting of a violent stop, or else the slip portion will not coast to the station. The hinged hooks, shackles, sliding bars or catches, etc, are made of wrought iron or steel, and case-hardened to withstand wear; they are usually well coated with oil. The cock-plugs, etc, are periodically treated with graphite or grease, so that they shall not stick nor work stiffly.

When attaching a slip-coach to the train, the coupling is never screwed up quite tightly; if this were done, it might put such a tension on the shackle or hook that the guard would be unable to release it. It is the guard’s duty to examine and test the slip apparatus before the train leaves the terminal. This especially applies to the cocks on vacuum pipe couplings; these are tested by getting the engine driver to blow up about 23-in of vacuum, when the guard pulls the string closing the cocks, disconnects the couplings, and examines the gauge in the van, which will indicate if air is leaking in.

When a slip is about to be made the slip guard, having satisfied himself that the signals are off, and that the train is running at the usual speed, applies the hand brake very slightly, to put a little “drag” on the coupling, closes the brake pipe cocks and releases the hook or shackle. He then applies his brake a little harder, and the two parts of the train separate. The train guard, as soon as he sees that the slip has been made successfully, gives the “all clear” to the engine driver, usually by showing his green flag - or a green light at night - from the window of his van, and the driver proceeds. Meanwhile, the guard of the slip portion releases the hand brake and lets his coaches coast along to the station, where he brings them to a standstill by the platform, either with a further application of the hand brake or by the continuous brake as described above.

On the Great Western Railway, one han dle does all the work. To slip the coach, or portion of the train, the guard pulls the lever right back to “slip and brake on” position; this applies the vacuum brake on the slip portion, and releases the coupling and hoses, which are automatically sealed by spring valves as the pipes separate. He then puts the lever back to “brake released” position, which puts the train pipe in communication with the vacuum reservoir; the coaches then coast into platform, where a further movement of the lever to “brake on” brings them to rest.

dle does all the work. To slip the coach, or portion of the train, the guard pulls the lever right back to “slip and brake on” position; this applies the vacuum brake on the slip portion, and releases the coupling and hoses, which are automatically sealed by spring valves as the pipes separate. He then puts the lever back to “brake released” position, which puts the train pipe in communication with the vacuum reservoir; the coaches then coast into platform, where a further movement of the lever to “brake on” brings them to rest.

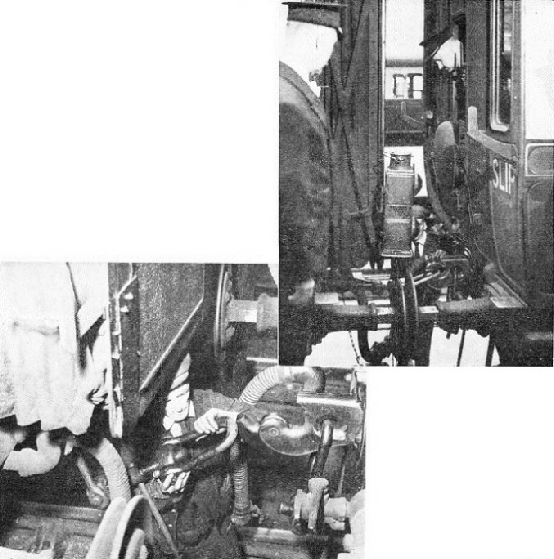

THE SLIP GUARD looking out of his window at the end of the slip coach after he has operated the slip lever.

Special means are used to identify the slip portions of trains in a visible way. At the rear end of the slip, the coach carries two lamps side by side, one red and the other white, encircled by red and white disks for day use. If two slips are run on the same train, the inner one carries this distinctive tail signal, but the outer one carries the lamps one above the other. When the “Cornish Riviera Express” carried three slips, a special tail-lamp arrangement had to be devised for the outermost one, and it was a triangle of three disk-encircled lamps, two red and one white.

In abnormal conditions of traffic, when many expresses are run in two or more portions, the slip portion is often promoted to be an independent train. When this happens it is hauled to its destination in the usual way. The enlarged slip portion may itself slip one or more coaches on its journey.

You can read more on “The Cornish Riviera Express”, “The Railway Carriage” and “Rolling Stock Construction” on this website.

dle does all the work. To slip the coach, or portion of the train, the guard pulls the lever right back to “slip and brake on” position; this applies the vacuum brake on the slip portion, and releases the coupling and hoses, which are automatically sealed by spring valves as the pipes separate. He then puts the lever back to “brake released” position, which puts the train pipe in communication with the vacuum reservoir; the coaches then coast into platform, where a further movement of the lever to “brake on” brings them to rest.

dle does all the work. To slip the coach, or portion of the train, the guard pulls the lever right back to “slip and brake on” position; this applies the vacuum brake on the slip portion, and releases the coupling and hoses, which are automatically sealed by spring valves as the pipes separate. He then puts the lever back to “brake released” position, which puts the train pipe in communication with the vacuum reservoir; the coaches then coast into platform, where a further movement of the lever to “brake on” brings them to rest.