A Novel Aspect of Railway Engine Designing

LOCOMOTIVES - 14

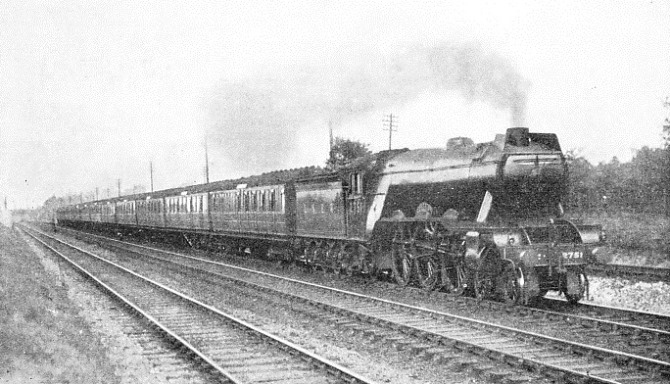

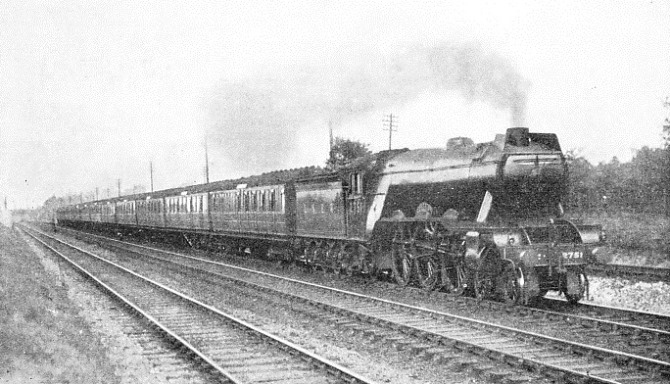

“HUSH-HUSH” ENGINE. No. 10000. This LNER locomotive is fitted with special wings which throw the smoke clear of the cab windows.

PERFECT visibility is one of the things which British locomotive engineers are striving to provide for their engine drivers to-day.

The factors which have given rise to the visibility problem are not difficult to explain. On every railway in the world tunnels and over-bridges set a maximum limit to the height to which a locomotive can be built. Since boilers continually grow in diameter, to give greater power, chimneys are forced to grow correspondingly shorter to avoid fouling overhead structures.

In Great Britain, where tunnels and over-bridges are particularly low-built, modern engines scarcely have any chimneys at all. The result is that the smoke and steam emitted in the chimney exhaust fail to clear the eddy currents set up by the boiler in motion. Instead of soaring high into the air, the smoke clings to the line of the boiler and often swoops down in front of the cab windows.

The nuisance is aggravated by the modern tendency of chimney exhausts to be more feeble than was usual in days gone by. This quietening of the exhaust has not been developed to promote the peace of those who live by the railway, but is the inevitable result of a certain trend in modern locomotive practice. It arises from the efforts made to use to the maximum possible the expansive properties of the steam before it is thrown to waste as exhaust from the engine chimney. Modern valve-motions are designed, and valves are set, in such a way that the modern locomotive works at a much earlier cut-off than its predecessors. That is to say, the percentage of the travel of the piston through which steam is being admitted to the cylinders is reduced, and the percentage through which it does its work by expansion is correspondingly increased. The greater the ratio of expansion, by so much is the pressure of the steam reduced before its work in the cylinders is finished, and it is this lower “terminal” pressure that causes the exhaust to drift lazily from the chimney at speed, as compared with the almost vertical column of exhaust - often accompanied, by reason of the fierceness of the blast, with cinders and sparks from the fire as well - that distinguishes the engine which is being worked less efficiently with a long cut-off. The faster the engine travels, so much the stronger become the mischievous eddy currents which tend to draw downwards this drifting exhaust, and so to spoil the driver's look-out.

Endeavours to eliminate smoke altogether by perfecting the combustion of the gases and black particles of carbon coming from the engine fire-box, have not been very successful. The present aim is to create counter currents of air even stronger than the boiler eddy currents and designed to deflect the smoke in the required upward direction.

Endeavours to eliminate smoke altogether by perfecting the combustion of the gases and black particles of carbon coming from the engine fire-box, have not been very successful. The present aim is to create counter currents of air even stronger than the boiler eddy currents and designed to deflect the smoke in the required upward direction.

“SUPER-PACIFIC” No. 2747 “CORONACH” with a section of its smoke-box cut away experimentally. The smoke-box was cut in this manner to make an air channel that would throw the smoke and steam clear of the driver’s vision.

An experiment on these lines was made with the famous LMS Engine “Royal Scot”, which is a three-cylinder type with a wide boiler and a particularly squat chimney. Two small upright wings were fitted, one on either side of the chimney, slightly closer together behind the chimney than in front. As the engine advanced, air rushed between the two wings, became compressed as the path narrowed, and shot upwards and backwards with increased velocity immediately in the rear of the chimney.

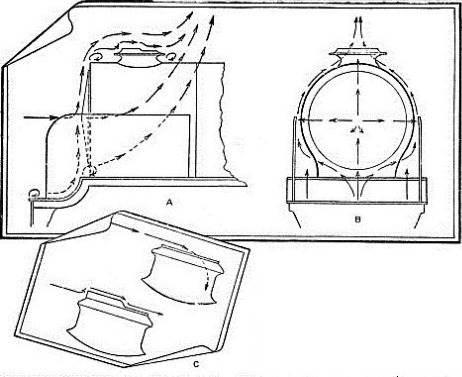

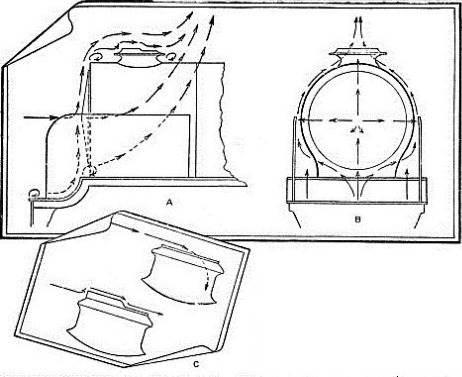

It was thought that this device, in company with a “capuchon” type chimney, would be sufficient to lift the smoke clear. A “capuchon” is a raised front lip on a locomotive chimney. The contrivance was originally intended as a remedy for the harmful down-draught in the chimney itself. Such a down-draught causes an imperfect vacuum within the smoke-box, thus hindering the proper “suction” of the smoke and gases coming through from the fire-box.

The additional fact, however, that a “capuchon” also acts as a smoke-deflector, even if only to a small extent, is now widely appreciated. The raised lip raises the path of the crosscurrent of air, causing it to rush over the top of the chimney clear of the offending back rim.

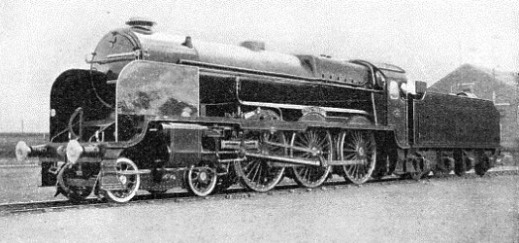

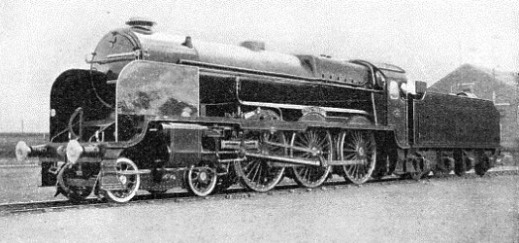

With the “Royal Scot” experiment it was soon found that the combined effects of the chimney wings and the “capuchon” were inadequate to clear the smoke from the driver's view-line. The small wings were accordingly removed and replaced by the large metal sheets with which the engine toured the North American Continent in 1933, and which are now such a familiar feature of the “Royal Scot” class.

Artificial Draught

These side screens, which owe their invention to German inspiration, are fixed vertically upon the running plate, one on either side of the smoke-box or front part of the boiler. All seventy “Royal Scot” type engines and many hundreds of British, French, Dutch, German, Turkish and other European locomotives have now been similarly fitted.

The reason for the success of these simple screens will become apparent after a brief study of the air currents which a moving locomotive sets in operation during many variations of speed.

When an engine is running at speed, the air with which it comes into contact is diverted in all directions at right-angles to the line of motion. A great “spreading-out” of air occurs at the centre of the boiler front, causing a partial vacuum to be set up all round and just behind the edges of this front face. The result of the partial vacuum is the formation of a ring of eddy currents surrounding the fore part of the boiler.

It is largely these eddies which cause the difficulty. They are liable to trap the cloud of steam and smoke emitted in the feeble exhaust of a fast-travelling engine, to whirl it down along the side of the smoke-box, and toss it in the very path that is the line of vision from the cab windows. Further, eddy currents forming behind the chimney dome and any other boiler projection all help to prevent the smoke from flying high into the air in the manner desired.

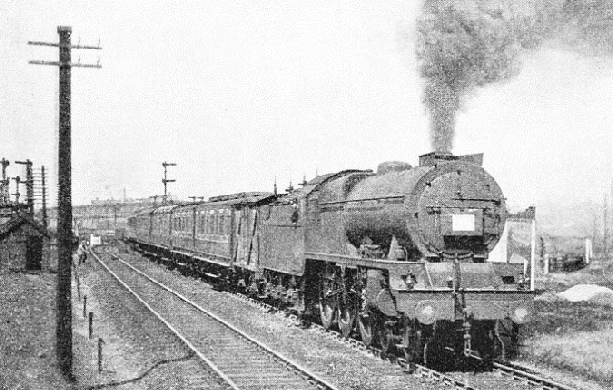

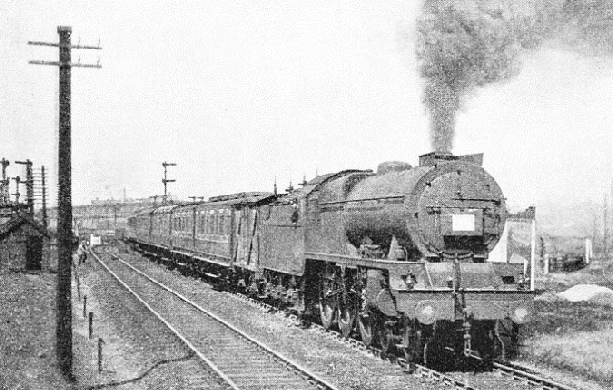

A “PACIFIC” locomotive, owned by the LNER, fitted with experimental smoke-deflecting device. Chimney wings have been mounted on a special sloping smoke-box.

The work of the side screens in preventing the nuisance is not difficult to understand. As the engine drives forward, causing an atmospheric “spread” in front, the outward rush of air impinges violently upon the side screens. For want of anywhere else to go, the air is immediately deflected upwards and, relative to the forward motion of the engine, backwards. Thus a strong up-draught is created directly in the rear of the chimney.

This artificial draught carries far greater force than the eddy currents, and ensures that the smoke will fly clear of the boiler barrel and away from the cab windows. If the screens are inclined inwards slightly at the top edges the effect is increased.

It is fortunate that, as the chimney exhaust becomes more feeble with increased speed of travel, when the engine is not labouring so hard, the up-draught caused by the side screens becomes automatically more violent. This is just what is wanted to keep the smoke clear at whatever speed the engine is travelling.

THIS SOUTHERN RAILWAY locomotive, “Lord Nelson” (right) is fitted with smoke-deflecting side screens and capuchon chimney.

On the European continent, where smoke-deflectors have been in use longer than in England, side screens of all shapes and sizes are to be found. In many instances the screens are placed as far away from the sides of the boiler as the regulations regarding locomotive width will allow; this provides a wider air passage than is adopted in England. Sometimes an artificial platform, placed above the running plate or horizontal main frame of the engine, is arranged to slope upwards on each side of the boiler-front at the base of the screens. This device increases the upward thrust of the draught when the engine is in motion.

In attempts to deflect engine smoke without the use of side screens, the London and North Eastern Railway has made several remarkable experiments. The most successful of the devices invented has turned out to be that applied to the “Hush-hush” high-pressure engine No. 10000. This partly streamlined locomotive has a boiler reaching up to the maximum limit permissible by tunnels. The chimney, therefore, has to be recessed, making the provision of powerful smoke-deflectors an essential item.

Diagrams A & B illustrate elevation and end view of side screens showing the flow of air currents when the locomotive is in motion. Diagram C shows how the down-draught in the chimney itself is prevented by the capuchon or raised front lip.

When Mr. H. N. Gresley, the Chief Mechanical Engineer of the LNER, was designing this experimental locomotive, he was assisted by Professor W. E. Dalby, of Glasgow University, in constructing a wooden model of the proposed engine. This model was placed in an air flume, or wind tunnel, and powdered chalk was blown up the chimney at the same time as a current of air was drawn through the flume at 50 miles per hour.

Through a glass window at the side of the flume it was possible to watch the course pursued by the powdered chalk. After several different designs of boiler-front had been tried on the model engine, an arrangement of smoke-deflectors was finally arrived at which lifted the whole of the powdered chalk sufficiently to clear the cab windows.

In this final design the outer shell of the boiler was made to culminate in two inward curved wings in front. The air path between these two wings narrowed from full boiler width ahead of the chimney to a small aperture behind it. The device was completed by a sloping smoke-box, and the full-sized edition of No. 10000 has proved the apparatus to be thoroughly efficient. At all speeds the smoke and steam is found to rise well clear of the driver's vision line.

THIS GERMAN “PACIFIC” locomotive is fitted with smoke-deflecting side screens which have a sloping base. This base is designed to increase the upward thrust of the draught when the train is in motion. Side screens were first used in Germany.

There is every likelihood that this particular type of smoke-deflector, with modifications to suit individual engines, will in time become a familiar feature of steam locomotives in many parts of the world. Mr. Gresley has already adopted a similar design for his famous engines of the “Cock o’ the North” type. In February, 1935, the first of a new series of high-speed Belgian “Pacific” engines shows us that the same idea is being tried out in Belgium.

A feature that is shared in common by No. 10000, by “Cock o’ the North”, and by the new Belgian “Pacific”, is the absence of chimney, dome, safety valve, feed-water-heater and all other appliances projecting above the top line of the boiler. This has reduced to a minimum the harmful eddy currents liable to spoil the efficient working of the smoke wings.

In the quest for reducing wind-resistance, so effecting fuel economies, British railways have not yet had recourse to that drastic form of streamlining that encloses the locomotive in a bullet-like steel casing, after the manner of the experiments now being made in Germany, America, and Japan. The Great Western Railway, however, is taking several of its “King” and “Castle” class engines in hand for partial streamlining at Swindon works.

The first engine to leave the works, No. 6014 “King Henry VII”, emerged from Swindon in its new form in March, 1935. The front of the smoke-box has not only been made semi-circular instead of flat; tapering or “teardrop” projections of steel plating have also been attached behind the chimney and safety valve. The streamlining applied in this instance, however, is exclusively for the purpose of reducing air resistance to the motion of the engine at speed, for the length of chimney possible with GWR tapered boilers is such that no trouble has ever been experienced from drifting exhaust.

It has been mentioned that the London and North Eastern Railway has made more than one experiment on the subject of smoke deflection. Mr. Gresley was not satisfied at the prospect of using standard side screens, such as those applied to the LMS “Royal Scot”, for his famous three-cylinder “Pacific” or 4-6-2 type express engines, and he cast about for new ideas. The first experiment he made was with “super-Pacific” No. 2747 “Coronach” - and an extraordinary experiment it was. Mr. Gresley had the upper part of the smoke-box door removed, and a new flat top to the smoke-box placed about 1½ ft below the level of the top of the boiler. But the old rounded smoke-box was left in position, apart from a large aperture “dug out” behind the chimney, which was left protruding up through the air space thus created.

This arrangement presented an unusual appearance. It was hoped that the movement of the engine would cause a suitable up-draught from the opening behind the chimney. In practice, however, the device proved unsuccessful, and “Coronach” has since been converted back to its original condition.

Mr. Gresley made a further experiment with No. 2751 “Humorist”, another “super-Pacific”. In this instance, a small wing was mounted on either side of the chimney upon a special sloping smoke-box. Once more, though, the effect of the contrivance did not come up to expectations.

These examples do show, however, that engineers to-day spare no pains in their attempts to dispel the varied difficulties which now attend the building of first-class locomotives. It is likely, moreover, that any simple device finally invented, which can successfully deflect the chimney exhaust of the LNER “Pacifics” without the use of side screens, will constitute a definite advance in the art of smoke-deflection.

AS AN EXPERIMENT, small smoke-deflectors were fitted to the LMS engine, “Royal Scot”. After trials had been held these small wings were replaced by a larger type of side screen.

You can read more on “Experimental Locomotives”, “Testing a Locomotive” and

“Unconventional Locomotives” on this website.

Endeavours to eliminate smoke altogether by perfecting the combustion of the gases and black particles of carbon coming from the engine fire-

Endeavours to eliminate smoke altogether by perfecting the combustion of the gases and black particles of carbon coming from the engine fire-